Dry-mix mortar, also known as dry-mix mortar or dry-mix powder, is made by drying, screening, and mixing fine aggregate, inorganic binders, and functional additives in a specific ratio. The production process includes sand pretreatment (such as drying and screening), precise ingredient metering, and thorough mixing. Strict weighing and proportioning, along with the appropriate amount of chemical additives, improve product quality and reduce environmental pollution.

Dry-mix mortar, also known as dry-mix mortar or dry-mix powder, is made by drying, screening, and mixing fine aggregate, inorganic binders, and functional additives in a specific ratio. The production process includes sand pretreatment (such as drying and screening), precise ingredient metering, and thorough mixing. Strict weighing and proportioning, along with the appropriate amount of chemical additives, improve product quality and reduce environmental pollution.

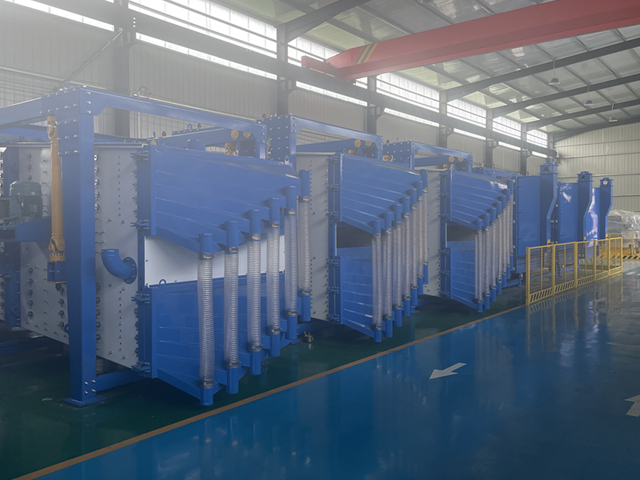

A dry-mix mortar production line generally includes a range of specialized dry-mix mortar equipment. These equipment, varying in type and function, together constitute a complete dry-mix mortar production line. Screening equipment such as square swing screens is responsible for systematic screening, grading, and impurity removal. The mixing system ensures thorough mixing of the raw materials, and the mixed mortar is systematically conveyed to the designated location via equipment such as bucket elevators and screw conveyors. Furthermore, material storage systems, dust collection systems, packaging systems, and automatic control systems for the dry-mix mortar equipment are all essential components, ensuring efficient and stable dry-mix mortar production.

Screening and grading equipment:

Ensures a balanced particle size distribution. Large variations in the particle size of aggregates (such as sand) in dry-mix mortar can affect workability. Screening classifies the aggregates by size and then mixes them in appropriate proportions to achieve the optimal particle size distribution.

Mixing and mixing equipment:

The mixing and mixing equipment used in dry-mix mortar production lines is known as dry-mix mortar mixers. This equipment comes in a variety of types and efficiently mixes and mixes materials, ensuring quality and efficiency during production.

Conveying system equipment:

The conveying system in a dry-mix mortar production line plays a crucial role, transporting materials from one location to another and ensuring smooth connections between equipment. Common conveying equipment includes bucket elevators, screw conveyors, and belt conveyors.

Material storage and dust collection system equipment:

The core component of the material storage system is the storage tank. Its size must be appropriately designed to ensure adequate material storage, and the quantity may vary depending on the specific situation. The dust collection system focuses on dust collection, thereby promoting environmentally friendly production in the dry-mix mortar production line.

When planning a dry-mix mortar production line, the first step is to conduct in-depth market research to gain insight into market demand, market capacity, and the production status of key competitors. By collecting and analyzing this key data, combined with your specific circumstances, you can accurately position yourself in the market and decide whether to focus on reducing the number of standard mortar production lines, developing specialty mortar lines, or developing both in parallel. Selecting the right equipment and production plan can improve product quality and production efficiency, creating greater commercial value for customers. Mirant Xinxiang Machinery can customize a complete set of dry-mix mortar production line equipment to meet the diverse needs of different customers, providing a one-stop shopping experience and turnkey projects.