In modern industry, which pursues high efficiency and large-scale production, the throughput and stability of the screening process directly determine the capacity of the entire production line. The square gyratory screen, with its unique structural design and efficient screening principle, has become a core supporting equipment for processing bulk materials and achieving high-yield, precise grading, playing a crucial role in many production lines.

Superior Structural Design and Production Line Adaptability

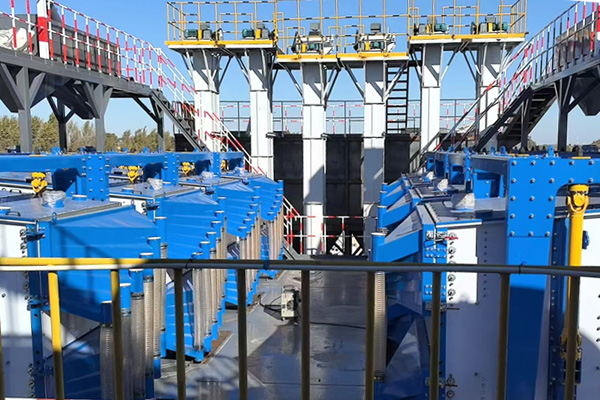

The most significant feature of the square gyratory screen is its rectangular screening area. Compared to a circular screen with the same floor space, it has a larger effective screening area and a longer material travel distance, allowing it to process more material at once, significantly increasing output per unit time. Its advantages are particularly prominent in production line integration:

- Efficiently receives upstream materials: Its wide rectangular feed inlet can easily accommodate wide material flows from large feeders, belt conveyors, or crusher outlets, reducing material accumulation and feed impact, achieving uniform material distribution.

- Multi-layer grading, multi-functional: The equipment can be configured with 1-5 layers of screens, accurately separating the input material into 2-6 different specifications of finished products and by-products in a single pass. The discharge ports are arranged along the length of the equipment, facilitating downstream diversion and collection via multiple conveyor belts or silos, greatly simplifying the process flow.

- Flexible Spatial Layout: The square structure allows for parallel or series arrangement within a factory, maximizing space utilization and enabling the construction of complex grading production lines.

Unique Oscillating Screening Principle and Efficiency

The excitation force generated by the square oscillating screen drive causes the screen body to perform a near-linear reciprocating oscillating motion in the horizontal plane. This motion trajectory results in unique screening effects:

1. High Processing Capacity: Under the action of horizontal acceleration, materials are rapidly dispersed and conveyed forward on the screen surface, resulting in extremely high processing capacity, particularly suitable for screening coarse particles or materials with a high specific gravity.

2. Particle Grading Approximate to a Screen Mesh: The relative motion between the material and the screen mesh is primarily horizontal. Particle passage depends more on their own size, reducing particle jumping and secondary crushing caused by vertical vibration. This results in high grading accuracy, making it particularly suitable for scenarios with strict requirements on particle size distribution.

3. Long lifespan and low maintenance: Smooth operation, low dynamic load transmitted to the supporting structure, reliable equipment operation, low requirements for plant foundation, and maintenance costs are far lower than some high-strength vibrating screens.

Square gyratory screens are an ideal choice for modern screening production lines to achieve large-scale, high-efficiency, and continuous production. They combine high throughput, high screening accuracy, and excellent operational stability, providing a solid equipment guarantee for improving the overall production line's capacity and economic benefits by optimizing material flow and grading efficiency.

The square gyratory screen, a core product of Mirant Xinxiang Machinery in the field of intelligent screening, has gained widespread customer recognition for its excellent screening and grading capabilities, providing solutions for screening production lines across numerous industries. With over 20 years of experience in the screening equipment field, we adhere to the principles of "quality assurance, reputation first, quality-oriented, and win-win cooperation," focusing on customer needs to ensure the manufacture of high-quality products that are stable in performance, of superior quality, aesthetically pleasing, and easy to operate.

Clearly separated particles, intelligent screening – Mirant Xinxiang Machinery Equipment Co., Ltd.