The performance of a screening system highly depends on the precise matching of its supporting conveying equipment. Different material characteristics, process requirements, and spatial layouts necessitate the selection of different types of conveying equipment. This article focuses on several commonly used conveying equipment in screening systems, analyzing in detail their working principles, applicable scenarios, selection considerations, and key technical points for coordination with screening machines.

1. Detailed Explanation of Core Equipment

- Bucket Elevator: The "Climber" of Vertical Space Utilization

Principle: The buckets vertically lift materials under the drive of a traction component.

Advantages: Small footprint, high vertical conveying efficiency.

Application Scenarios: Used in multi-layer screening or when materials need to be lifted to high-level screening machines/silos.

- Belt Conveyor: The "Main Artery" of Material Flow

Principle: A circular belt carries and conveys materials under the drive of a drive drum.

Advantages: Large conveying capacity, long distance, low energy consumption, and stable operation.

Selection Considerations: Belt width, belt speed, and inclination angle (to prevent material slippage); belt type (wear-resistant, non-stick, high-temperature resistant); when used for finished product discharge, multiple parallel conveyors are often used to achieve synchronous output of multiple stages of products.

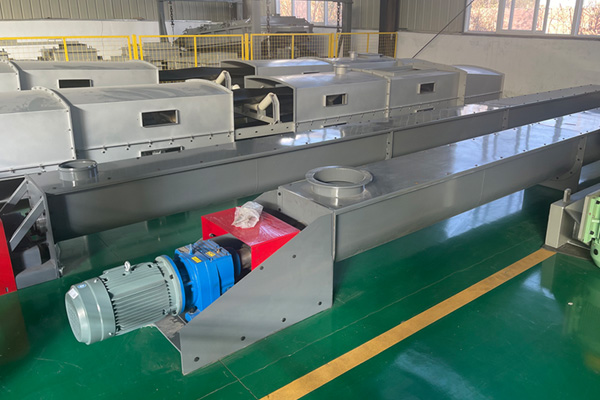

- Screw Conveyor: A "Hidden Channel" for Powdered and Small Particle Materials

Principle: Rotating helical blades propel the material axially within a sealed trough.

Advantages: Compact structure, good sealing, and multiple loading and unloading points.

Selection Considerations: Suitable for powdery, granular, and slightly sticky materials; not suitable for easily perishable, easily broken, or highly entangled materials. Commonly used for horizontal or slightly inclined conveying of undersize fines.

- Vibrating Feeder: A "Precision Valve" for Pre-Screen Feeding

Principle: A vibrating motor drives the trough to vibrate reciprocally, causing the material to jump forward along a parabolic trajectory.

Advantages: Uniform feeding, adjustable, and easy to achieve sealing and quantitative control.

Key selection criteria: Material particle size, moisture content, and flowability; required feeding capacity and precision; installation angle and height difference between the screen and the feed inlet.

2. Key Technical Considerations for Coordinating with a Screening Machine

- Feeding Point Design: The material drop point of the feeding equipment (such as a vibrating feeder) should be located in the middle of the screening machine's feed hopper. Buffer plates or guide plates should be used to reduce the impact of material on the screen, ensuring uniform material distribution across the entire screen width.

- Synchronization and Interlocking: The starting sequence of the conveying system should follow the principle of "starting in reverse flow and stopping in forward flow," and should be electrically interlocked with the screening machine to prevent material blockage or equipment idling.

- Dust Control and Environmental Protection: All transfer points (especially the connections between the screening machine's inlet/outlet and the conveying equipment) must be properly sealed, equipped with dust hoods or flexible connections to control dust leakage.

There is no "best" conveying equipment, only the "most suitable" choice. Engineers must comprehensively consider material characteristics, process parameters, environmental conditions, and investment costs to conduct refined selection and integrated design, ensuring that the conveying and screening equipment work in harmony and maximize the system's potential.