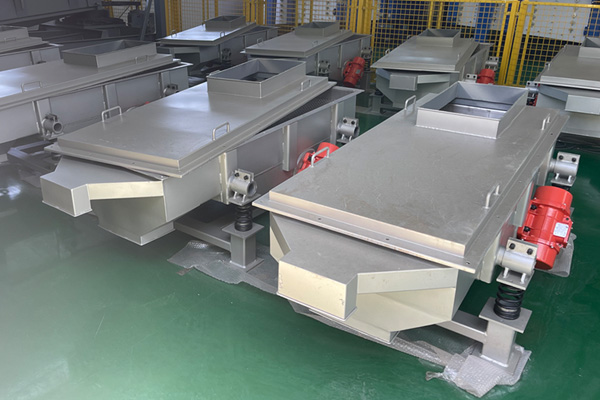

Linear vibrating screens use two synchronously counter-rotating vibrating motors to generate vibration, causing the material to move linearly across the screen surface in a bouncing motion. They are widely used in various manufacturing companies for screening and grading dry powders and granular materials. Some users fail to accurately select the right model, resulting in poor screening performance. Today, we will discuss several key factors to help you choose the right screening equipment for your production needs, providing a reference for your selection decision.

1. Screening Material Characteristics: First, determine the size of the material being screened, its specific gravity, and whether it is sticky or wet. These factors directly affect the screening performance and the selection of a linear vibrating screen. Only by understanding the material's properties can you better select a linear vibrating screen.

2. Screening Material Mesh Size: Mesh size is also a key consideration for screen selection. Linear vibrating screens can be configured with 1-6 screen layers to simultaneously grade up to seven material sizes. The larger the screen size, the higher the output. A larger mesh size results in a smaller screen size. Understanding the mesh size of the material being screened is crucial for accurate selection.

3. Screening Capacity Requirements: Select a linear vibrating screen based on your actual production and screening throughput. The amount of material passing through the screen primarily depends on the width of the linear vibrating screen. The greater the production capacity, the wider the screen surface needs to be.

4. Production Environment and Special Requirements: The manufacturer's actual application environment also influences the selection of a linear vibrating screen, including factors such as space limitations, hygiene standards, and the need for explosion-proofing.

5. Comprehensive Supplier Evaluation and Service: A quality equipment supplier can provide comprehensive support to the user, including technical capabilities, on-site project examples, and service terms.

Based on the above introduction to the five factors that influence linear vibrating screen selection, users can systematically consider these key points when selecting a linear vibrating screen, establishing a scientific selection framework. After finalizing the selection plan, conduct material testing (most manufacturers offer free sample testing) and collect detailed screening solutions from suppliers for comparison. The screening equipment that suits you best is not necessarily the most technologically advanced one, but rather the equipment selection solution that best matches your screening material characteristics, production scale, and process requirements.

As the core product of Mirant Xinxiang Machinery's intelligent screening equipment, linear vibrating screens have been recognized by customers for their solutions in screening production lines across numerous industries. They are widely used in manufacturing companies for screening and grading dry powders and granular materials. Customizable in various sizes and specifications, they provide a strong foundation for your production and development.