The gyratory screen has become one of the preferred screening equipment for screening and grading in numerous industries, thanks to its high precision and high throughput. By performing three-dimensional motion (horizontally, vertically, and tilted) to simulate a "shaking and tapping" motion, the square vibrating screen effectively addresses the problems of traditional vibrating screens, such as clogging and low screening efficiency, while maintaining screening accuracy. To gain a more intuitive understanding of the square vibrating screen, today we will discuss its structure and reveal the key to its efficient screening.

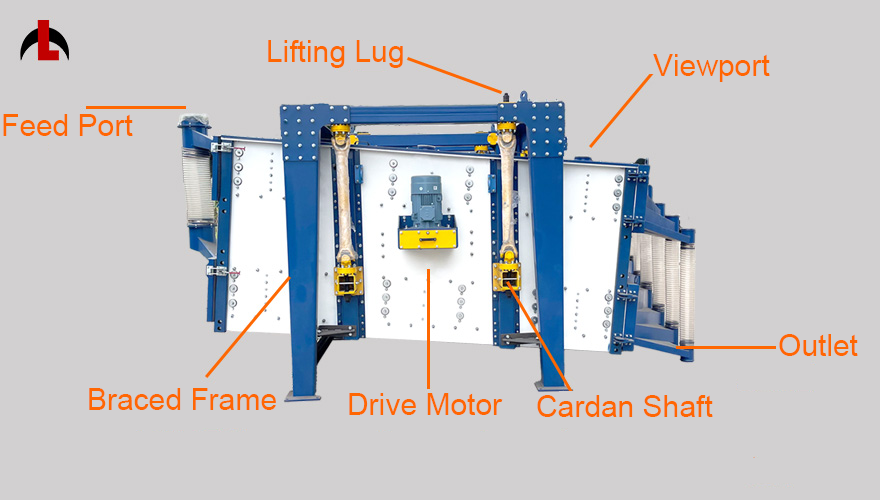

The gyratory screen consists of a screen box, screen mesh, vibrator, drive motor, support device, and inlet and outlet ports.

The screen box, with its main body in a square shape, is typically constructed of carbon steel or stainless steel. It can accommodate multiple layers of screen mesh, responsible for carrying and screening the material. Its right-angled structure ensures enhanced airflow at the edges of the screen frame, effectively preventing material accumulation at the edges.

The screen assembly, a key component, is typically constructed of stainless steel or nylon, offering excellent wear and corrosion resistance. Different mesh sizes can be selected based on screening requirements. A bouncing ball cleaning device is installed at the bottom of the screen frame, utilizing the impact force generated by the movement of the screen body for automatic cleaning.

The vibrator, driven by a motor, generates horizontal oscillation and vibration in the screen box, providing both horizontal rotational force and vertical excitation force. It is the core component of the screen box's motion. Its design directly impacts screening uniformity and efficiency, and its accuracy and stability are crucial.

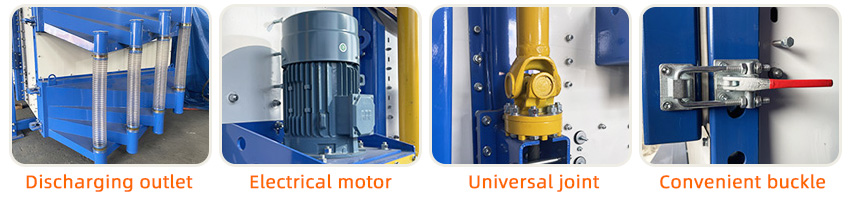

The drive motor provides power to the vibrator, and its power and frequency can be adjusted according to the material characteristics to achieve optimal screening results.

The supporting device is usually a universal joint and a steel structure frame to ensure the stability of the equipment.

The inlet and outlet, including the feed hopper, distributor, and outlet, are responsible for evenly distributing the material to be screened onto the screen surface and discharging both screened and unscreened material.

As Mirant Xinxiang Machinery core intelligent screening equipment, the gyratory screen, with its excellent screening and grading capabilities, has been widely recognized by customers for its solutions in screening production lines across numerous industries. We consistently adhere to the principles of "quality assurance, reputation first, quality-oriented, and win-win cooperation," and are guided by customer needs to ensure the manufacture of high-quality products with stable performance, excellent quality, attractive appearance, and easy operation.

Clearly separated particles, intelligent screening— Mirant Xinxiang Machinery.