The 2600 tumbler screen has a screen diameter of 2530 mm, a screening area of 5.3 square meters, a 5.5 kW motor, a screen angle of 0-10 degrees, and can be freely configured with 1-5 screen layers, achieving a maximum separation of 6 levels. It effectively simulates the principles of manual screening, offering high throughput and precision.

The 2600 tumbler screen consists of a screen box, drive unit, shock-absorbing springs, inlet and outlet ports, base, and bracket.

The screen box, the core component of the screening process, typically consists of a screen, screen frame, and liner, responsible for screening, removing impurities, and grading the material.

The drive unit, the key component that enables the screen box to swing, generates power from a motor or vibrator, causing the screen box to swing in three dimensions.

The shock-absorbing spring, a rotary spring or rubber spring installed at the bottom of the screen box, provides both shock absorption and sufficient swing amplitude for effective screening.

The inlet and outlet, including the feed hopper, distributor, and outlet, are responsible for evenly distributing the material to be screened onto the screen surface and discharging both screened and unscreened material.

The base and bracket ensure the overall stability of the screen box.

Dynamic diagram of the working principle of 2600 tumbler screen

Dynamic diagram of the working principle of 2600 tumbler screen

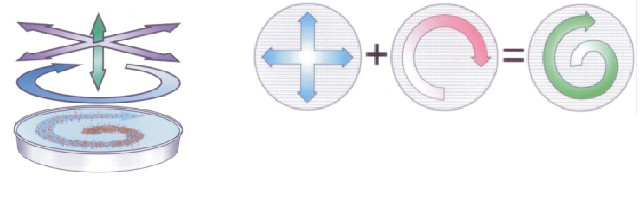

2600 tumbler screen motion trajectory

Working Principle of the 2600 tumbler screen :

The material first enters the screen evenly through the feed inlet. The swinging motion of the screen box causes the material to spirally disperse, preventing accumulation and ensuring efficient screening. Subsequently, a motor-driven eccentric block generates a three-dimensional swinging motion, causing the material to continuously tumble and disperse on the screen. Fine particles pass through the screen and fall to the lower layer, while coarse particles are discharged from the outlet of the current layer. Finally, after being graded by multiple screens, materials of different particle sizes are discharged from their respective outlets, completing the screening, impurity removal, and grading process.

Features of the 2600 tumbler screen :

Up to 5 times the output per unit area, with precise six-level separation;

Screening efficiency ≥ 95%, using a high-efficiency screen cleaning system;

Fully enclosed structure, sealed dust removal, and safe operation;

Pneumatic device, fast screen change, and easy maintenance;

Noise level < 75dB, optimized gravity balance, and low dynamic load on the foundation.

As one of Mirant Xinxiang Machinery's core products in the intelligent screening field, the tumbler screen has earned widespread recognition from customers for its superior screening and grading capabilities, serving as a solution for screening production lines across numerous industries. We consistently adhere to the principles of "quality assurance, reputation first, quality-oriented, and win-win cooperation," and are guided by customer needs, ensuring the manufacture of high-quality products with stable performance, superior quality, attractive appearance, and easy operation.

Clearly separated particles, intelligent screening— Mirant Xinxiang Machinery.