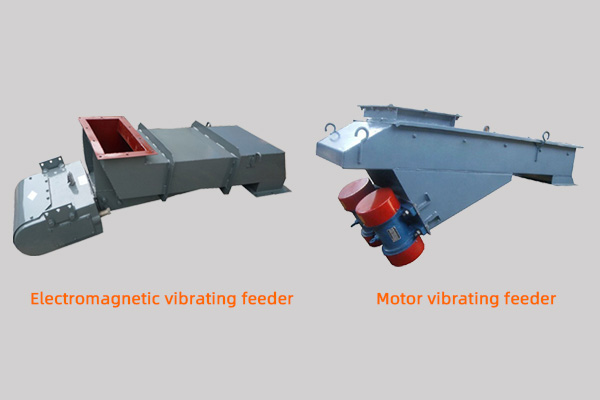

Although electromagnetic vibrating feeders and electric motor vibrating feeders share similar names, their operating principles, performance characteristics, and application scenarios differ fundamentally. Simply put, the core difference lies in the driving source and the method of generating vibration:

Electromagnetic vibrating feeders use electromagnets to generate suction, directly driving the trough to vibrate.

Electromechanical vibrating feeders utilize a conventional motor to rotate an unbalanced mass (vibrating motor), generating centrifugal force to drive the trough to vibrate.

Below, we provide a detailed comparison of electromagnetic and electric motor vibrating feeders from several perspectives, hoping to assist you in selecting the right equipment.

Electromagnetic Vibrating Feeder

Working Principle:

Electromagnetic drive: Components such as thyristors regulate the input current to the electromagnet (half-wave rectification), causing the electromagnet to engage and release the armature at a high frequency (such as 50Hz or 100Hz), driving the trough to vibrate.

Vibration Frequency:

High frequency, small amplitude: Typically 3000 vibrations/minute (50Hz power supply) or higher. The amplitude is small (typically around 1-2mm).

Feed Adjustment Method:

Stepless Control: By varying the input current (adjusting the conduction angle of the thyristor), the amplitude is smoothly and precisely controlled, thereby steplessly adjusting the feed rate. This control is very convenient and easily automated.

Performance Characteristics:

Advantages:

• High control accuracy, fast response, and uniform and stable feeding.

• No lubrication points required, requiring minimal maintenance.

• Low power consumption.

• Quick start and stop, with virtually no inertia.

Disadvantages:

• Low power consumption, unsuitable for conveying bulky, heavy, or wet, sticky materials. • Relatively loud noise during operation (high-frequency humming).

• Slightly affected by voltage fluctuations.

Main Applications:

Precise, lightweight dosing: Commonly used in the chemical, food, pharmaceutical, and plastics industries for precise batching and quantitative packaging of powdered and granular materials, and for feeding automated production lines.

Motor Vibrating Feeder

Working Principle:

Mechanical inertia drive: A conventional three-phase or single-phase asynchronous motor drives the eccentric weights (unbalanced weights) at each end of the shaft to rotate at high speed, generating centrifugal force, resulting in directional vibration.

Vibration Frequency:

Low frequency, large amplitude: Typically 700-1500 rpm (synchronized with the motor speed). Amplitude is large (up to 2-8mm or even larger).

Feed Adjustment Method:

Adjustment is relatively complex: 1. Amplitude adjustment: Manually adjust the angle of the eccentric weights after stopping the machine. 2. Frequency adjustment: Requires a frequency converter to change the motor speed. Feed rate is generally fixed, and fine adjustment is not as convenient as with electromagnetic feeders.

Performance Characteristics:

Advantages:

• High power and conveying capacity, suitable for high flow rates and heavy loads.

• Sturdy and durable structure, adaptable to a wide range of materials (including large and high-temperature materials).

• Relatively low operating noise (low-frequency rumble).

Disadvantages:

• Inertia during starting and stopping, unable to stop instantly.

• There are parts such as bearings that require regular lubrication, so the maintenance workload is slightly higher.

A simple analogy:

An electromagnetic vibrating feeder is like a smartphone: precise control, sophisticated functions, and responsiveness, suitable for delicate operations.

An motor vibrating feeder is like a feature phone (Elderly phone): powerful, durable, and with long battery life, it's suitable for basic but reliable calls.

We hope this detailed comparison will help you make the right choice!

Clearly separated particles, intelligent screening— Mirant Xinxiang Machinery.