Say Goodbye to Inefficiency! How Does a Square Gyratory Screen Solve Your Screening Pain Points?

Are you often troubled by these problems in your daily production?

- The screen clogs easily, requiring cleaning several times a day?

- The desired fine powder cannot be sieved, resulting in consistently lower output?

- Good granular materials are mostly broken after sieving?

- The equipment is too noisy, creating a frustrating working environment?

If you relate to any of these issues, then it's time to meet the square gyratory screen—the all-rounder that solves all your screening problems!

How Does a Square Gyratory Screen Solve Your Screening Pain Points?

Scenario 1: Processing sticky, lightweight materials (such as flour, starch, and traditional Chinese medicine powder)

Pain Point: Easily adsorbs and clumps, causing severe screen clogging.

Solution: The gentle planar gyratory motion of the screen, combined with the continuous impact of bouncing balls under the screen, effectively breaks up clumps, allowing materials to pass through smoothly and eliminating frequent manual cleaning.

Scenario 2: Processing Fragile Crystals/Particles (e.g., Sugar, MSG, Resin)

Pain Point: Traditional vibrating screens have high impact force, resulting in a high material breakage rate, affecting appearance and selling price.

Solution: Near-horizontal swaying motion allows materials to "walk" smoothly on the screen surface rather than "jump," perfectly protecting material integrity. Reducing loss means increasing profits.

Scenario 3: Requires High-Precision Grading (e.g., Metal Powder, Abrasives)

Pain Point: Ordinary screening lacks precision and efficiency, resulting in mixing of different grades of materials.

Solution: Materials stay on the screen surface for a longer time, with a longer movement trajectory, resulting in more thorough screening. This allows for precise particle size control, easily obtaining high-purity products of 2-6 grades.

Scenario 4: Limited Space, Diverse Needs

Pain Point: Limited factory space prevents the placement of multiple machines.

Solution: Compact square structure, stackable in multiple units, allowing one machine to perform the work of multiple machines, saving you valuable production space.

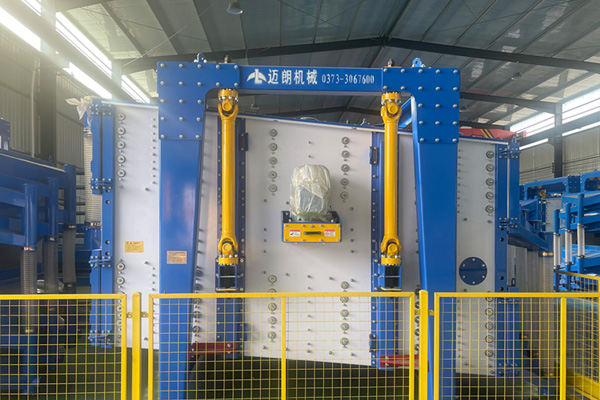

Choosing a square gyratory screen means choosing a more efficient, cleaner, and more economical production method. It's not just equipment; it's a strategic partner for enhancing product competitiveness and achieving lean manufacturing. We offer square gyratory screens in various specifications, supporting customization services (number of screen layers, material, size, etc.), and provide comprehensive installation, commissioning, and after-sales support. Say goodbye to screening hassles in your production, ensuring smoother operation and easier management!

Clearly separated particles, intelligent screening – Mirant Xinxiang Machinery Equipment Co., Ltd.