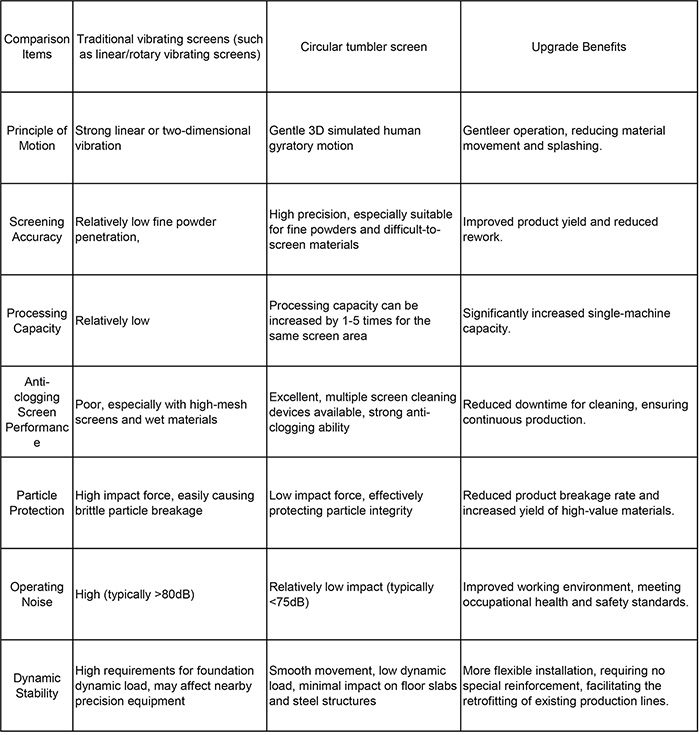

Many existing production lines still use old-fashioned linear vibrating screens or rotary vibrating screens. With increasingly stringent requirements for product quality, capacity, and production environment, these traditional devices are gradually revealing problems such as low precision, easy clogging, high breakage rates, and noise pollution. Upgrading to circular gyratory screens has become a wise choice for enterprises to achieve a leap in production line efficiency.

I. Comparison of direct benefits of upgrading and replacing circular gyratory screens

II. Key Points for Production Line Upgrades

1. Space and Interface Compatibility: Circular gyratory screens are typically compact, occupying a similar or even smaller area than older equipment. Upgrades should focus on matching the feed inlet height, discharge outlet direction and size, power supply, and control interfaces to ensure smooth integration with upstream and downstream equipment.

2. Process Parameter Optimization: Utilizing the adjustable eccentricity and rotation speed of the gyratory screen, fine-tuning parameters based on the characteristics of the existing materials can find the optimal balance between output and accuracy, often resulting in better screening performance than the original process.

3. Automation Integration: Integrating the new gyratory screen into the existing PLC or DCS control system enables remote start/stop, status monitoring, and fault alarms, improving the overall automation level of the production line.

4. Maintenance Mode Transformation: Gyratory screen maintenance is relatively simple, but targeted training is required for operators and maintenance personnel to ensure they master new equipment maintenance knowledge (such as screen replacement and bearing lubrication).

III. Applicable Upgrade Scenarios

-Product upgrades leading to increased screening accuracy requirements.

-Insufficient capacity of existing screening machines, becoming a production bottleneck. - Changes in material properties (e.g., finer, more viscous) render existing screening machines inadequate.

- There is an urgent need to reduce production noise and dust to meet environmental and safety regulations.

- There is a desire to reduce material breakage and improve product quality and economic efficiency.

Upgrading traditional screening equipment in the production line to a circular gyratory screen is not a simple equipment replacement, but a technological transformation that brings comprehensive improvements in precision, output, environmental protection, and maintenance. It helps companies overcome existing process bottlenecks with relatively small investments, providing an efficient path to achieve intelligent and refined upgrades to the production line, injecting new momentum into market competition.

Clearly separated particles, intelligent screening – Mirant Xinxiang Machinery Equipment Co., Ltd.