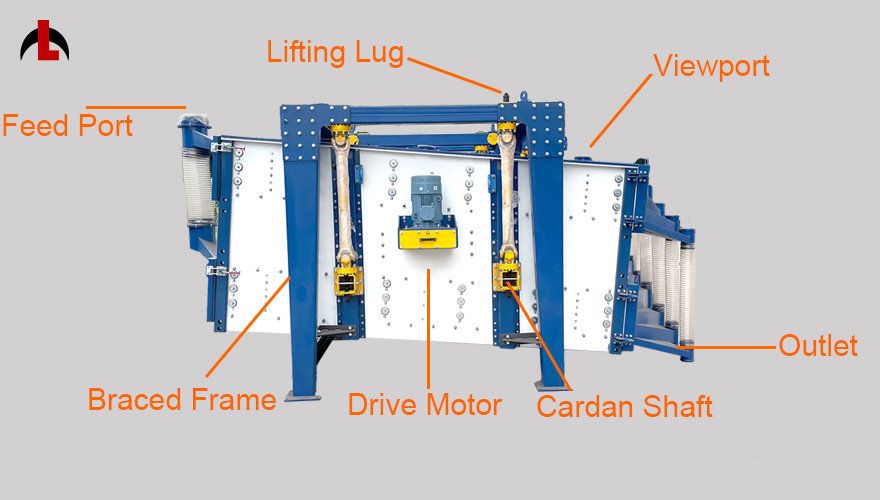

With unique design of high efficiency, high precision and large output, Gyratory Sifter is widely used in chemical industry, metallurgy, no-ferrous metal industry, food, abrasives and other industries.

It simulates the motion of human hands sieving, combining "sieve" motion (planar circular motion) and "dustpan" motion (throwing materials upwards), which can quickly spread the material across the full width of screen at the feed end and drive the particles moving forward to touch the screen surface with high capacity and high efficiency.

When it is started, the screen machine body——the screen box——shakes in reciprocating motion, and the inertial force of the screen box rotating back and forth drives the screen surface to shake periodically, so that the material on the screen surface makes a directional jumping motion. With the screen box, the physical screen with a smaller aperture than the screen surface drops to a lower level and becomes a fine screen. The material with a larger aperture than the screen surface is discharged from the discharge port after continuous rolling and jumping motion, and the screening work is finally completed.

The reciprocating swing motion can quickly disperse the material for easy screening,which can quickly send the material to the screen surface with almost no vertical vibration and jumping. Small materials pass through the screen surface quickly, while large particles are gradually transported to the discharge end.

1. Self-cleaning for the sieve mesh.

2. Optional from single feed 1-5 layers to double feed design up to 10 layers.

3. Suitable for multi-level and multi-material screening.

4. High accuracy, production capacity and high utilization rate, combined discharge.

5. All-round swing, automatic discharging, suitable for ssembly line production.

6. Simple structure, big capacity and high screening efficiency.

From the perspective of the motion trajectory of the screen box, the Gyratory Sifter is also called Square Swing Vibrating machine or Suspended Composite Screen. The exciting force generated by its driving device is the inertial force formed by the rotation of the eccentric wheel around the fixed axis. According to the structural characteristics and working principle of the swing screen, the screen surface is generally arranged horizontally or slightly inclined (the angle is 0°-5°).

The Gyratory Sifter is widely used in metallurgy, refractory materials, ores, ceramic particles, mining, such as frac sand, chemistry, plastics, grain, food, chemical industry, biology, sugar making, salt making, MSG, starch, activated carbon, silicon carbide, soda ash, citric acid, EPS, medicine and other industries that require high purity and large output screening.

Model | ML1030 | Ml1036 | ML1230 | ML1236 | ML1530 | ML1536 | ML1830 | ML1836 | Ml2030 | ML2036 |

A(mm) | 3840 | 4442 | 3842 | 4442 | 3842 | 4442 | 3840 | 4442 | 3842 | 4442 |

B(mm) | 1700 | 1700 | 1900 | 1900 | 2200 | 2200 | 2500 | 2500 | 2700 | 2700 |

C(mm) | 1917 | 1917 | 1917 | 1917 | 1917 | 1917 | 1917 | 1917 | 1917 | 1917 |

Screen area(㎡) | 3 | 3.6 | 3.6 | 4.32 | 4.5 | 5.4 | 5.4 | 6.48 | 6 | 7.2 |

No. of screen layers | 1-5 | 1-5 | 1-5 | 1-5 | 1-5 | 1-5 | 1-5 | 1-5 | 1-5 | 1-5 |

Voltage(v) | 380 | 380 | 380 | 380 | 380 | 380 | 380 | 380 | 380 | 380 |

Frequency(r/min) | 180-260 | 180-260 | 180-260 | 180-260 | 180-260 | 180-260 | 180-260 | 180-260 | 180-260 | 180-260 |

Power(kw) | 3.0 | 3.0 | 4.0 | 4.0 | 5.5 | 5.5 | 7.5 | 7.5 | 7.5 | 7.5 |

Screen angle(°) | 5-8 | 5-8 | 5-8 | 5-8 | 5-8 | 5-8 | 5-8 | 5-8 | 5-8 | 5-8 |

Screen stroke(mm) | 25-60 | 25-60 | 25-60 | 25-60 | 25-60 | 25-60 | 25-60 | 25-60 | 25-60 | 25-60 |

Q1: How to chose the suitable model?

LPls kindly let us know below details:

a. Required capacity, e.g. 200kg/hour.

b. Layers of screens, e.g. 2 layers.

c. Screen mesh size, or ( Material size /particle size. e.g. 1mm or 20 mesh.)

d. Material name, water content ratio. e.g. dried flour powder.

e. Other special requirement.

Q2: What's usually local power supply ______Voltage& ______Frequency in your city ?

Various power voltage: 110V 200V 240V 380V 415V 450V 550V

Power Frequency: 50HZ 60HZ or Single phase electricity

Q3: What's material for machine do you need?

A Stainless steel 304

B Carbon steel Q235

C Touching parts SUS304

Q4: Warranty?

You have 12 month guarantee, we provide 100% original spare parts and online support if any breakdown in warranty period.

Q5: How to ensure the machine work good with the material?

We can test you material in the machine before shipping and you see process in video.