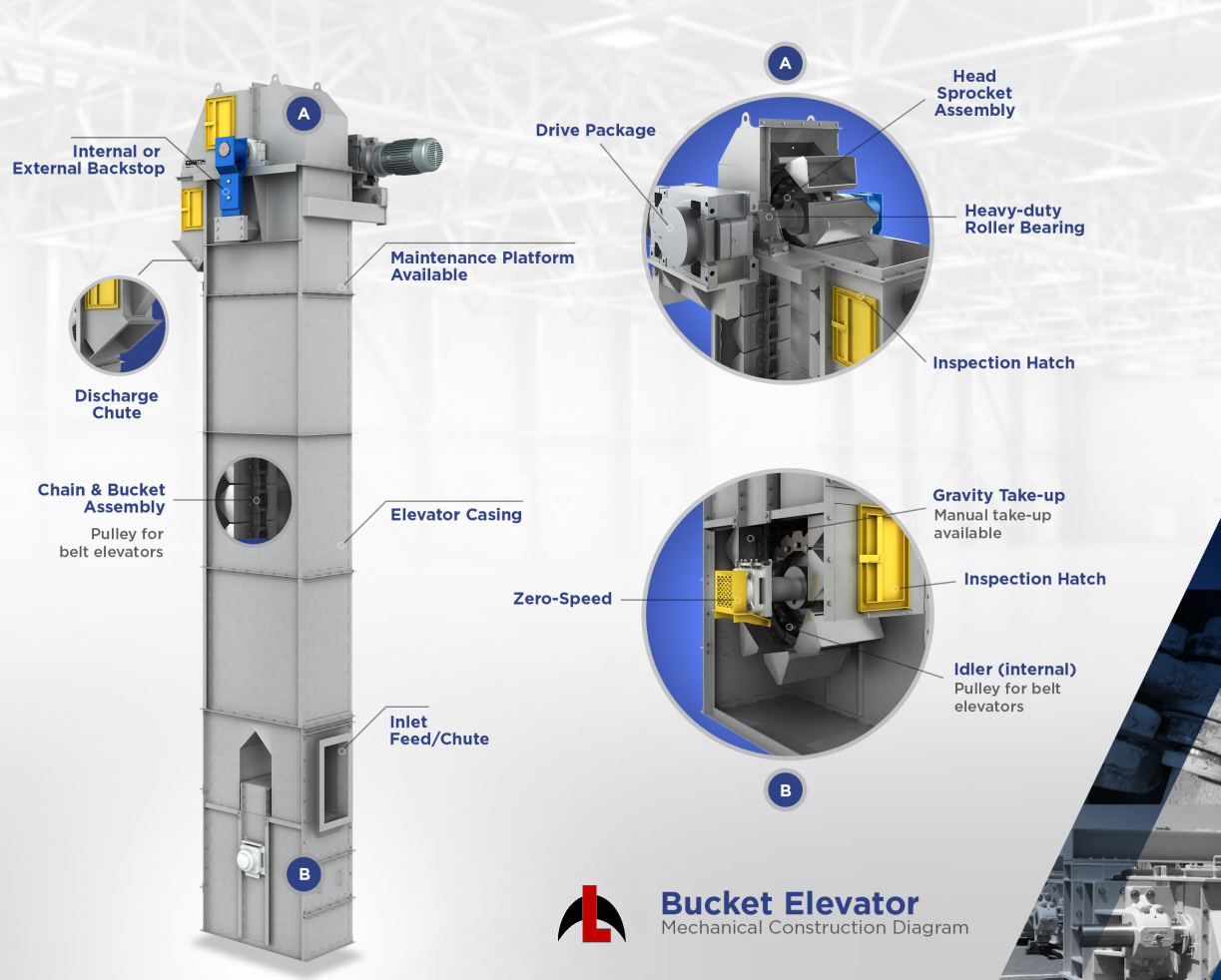

Mirant's Bucket elevator is a plate chain type, gravity induced lifting equipment. It adopts inflow feeding, the material flows into the plate chain and is lifted to the top, and then unloads automatically under the action of material gravity.

The transmission capacity can be adjusted according to the transmission speed, and the height can be selected according to the needs.

Mirant's Bucket Elevator is a plate chain type, gravity-induced lifting equipment with excellent structure, good steel type and high precision. The machine adopts inflow feeding. The material flows into the hopper and is lifted to the top by the plate chain, and unloads automatically under the action of the material gravity. The casing is folded and convex in the middle, and has good rigidity and beautiful appearance after welding. Low cost of use, good sealing performance, high feeding accuracy, low maintenance cost, energy saving and environmental protection.

1. High efficiency:

The inflow feeding system adopted by the bucket elevator during operation can make the material almost free of return and digging during the operation of the machine, reducing the invalid power.

2. Long service life:

After research and development and the application of scientific and technological technologies, the bucket elevator can effectively improve its working efficiency, reduce its breakage and damage rate, thereby enhancing its use efficiency and improving its service life.

3. Save space:

The bucket elevator can transport materials in a vertical direction, so it occupies a small area, which can effectively help us save space and reduce site costs.

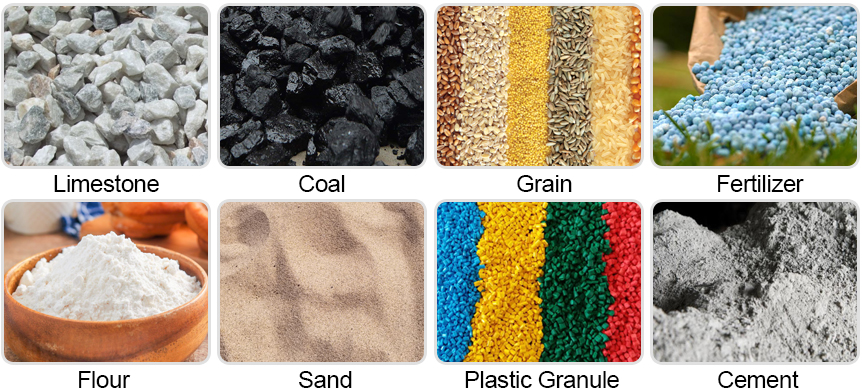

Mirant's Bucket Elevator uses belt or chain bucket to lift abrasive, granular, block materials, such as grain, coal, cement, ore, clay and other materials. Since its traction mechanism is a circular chain, it is allowed to convey materials with higher temperatures (material temperature does not exceed 250°). The half-conveying and lifting height can reach 40 meters and the highest can reach 80 meters.

| Model | Conveying capacity(m³/h) | Bucket speed(m/s) | Spindle speed(r.p.m) | Material size(mm) | Bucket capacity(L) | Bucket width(mm) | Bucket distance(mm) |

| NE15 | 15 | 0.5 | 15.54 | <40 | 2.5 | 250 | 203 |

| NE30 | 32 | 0.5 | 16.54 | <50 | 7.8 | 300 | 305 |

| NE50 | 60 | 0.5 | 16.54 | <50 | 15.7 | 300 | 305 |

| NE100 | 110 | 0.5 | 14.13 | <70 | 35 | 400 | 400 |

| NE150 | 170 | 0.5 | 14.13 | <70 | 52.2 | 600 | 400 |

| NE200 | 210 | 0.5 | 10.9 | <100 | 84.6 | 600 | 500 |

| NE300 | 320 | 0.5 | 10.9 | <100 | 127.5 | 600 | 500 |

| NE400 | 380 | 0.5 | 8.3 | <120 | 182.5 | 700 | 600 |

| NE500 | 470 | 0.5 | 7.1 | <120 | 260.9 | 700 | 700 |

| NE600 | 600 | 0.5 | 7.1 | <120 | 33.2 | 700 | 700 |

| NE800 | 800 | 0.5 | 6.2 | <140 | 501.8 | 800 | 800 |

To proper selection of Bucket Elevator for you? Tell us the followings question:

A: OuWhat's material will be transported by bucket elevator? And the density of material? also the temperature of material? And it's size?

B: What's height of the bucket elevator as you want?

C: What's capacity of the bucket elevator as you want? 100t/h, 500t/h?

We can provide various kinds of Bucket Elevator (lifting machine), pls choose the following which one is suitable for you?

· TH ring chain bucket elevator

· NE plate chain bucket elevator

· TB plate chain bucket elevator

· TDG/THG efficient bucket elevator

· TZD silo bucket elevator