Mirant's Electromagnetic Vibrating Feeder is a linear feeding device. It can realize quantitative feeding and conveying of bulk, granular and powdered materials. The feeding process is continuous and can be controlled at any time.

The material is thrown upward and leaps up in the form of a parabola, so that the material moves forward continuously and evenly, realizing quantitative feeding.

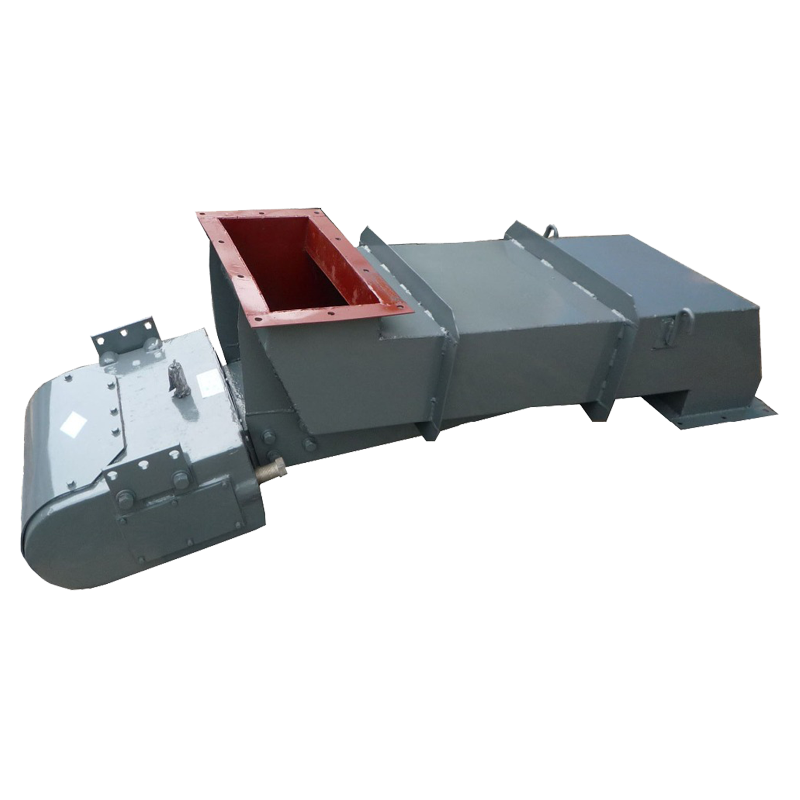

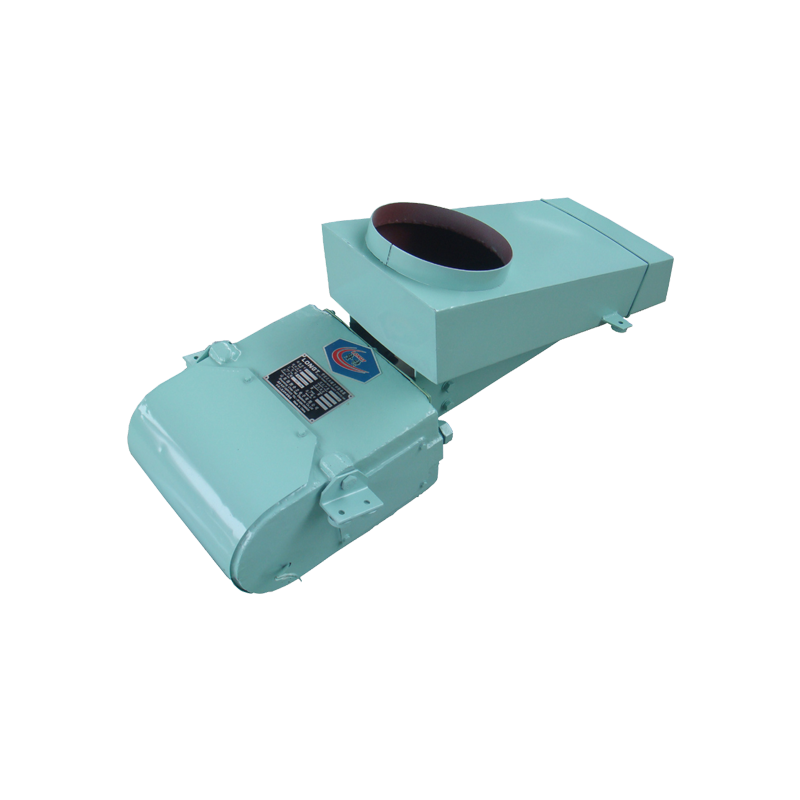

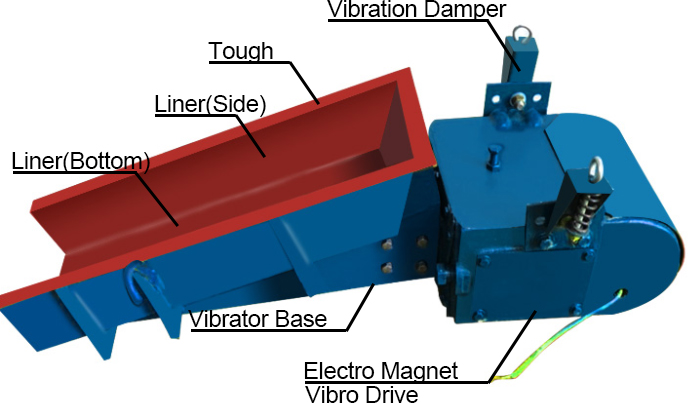

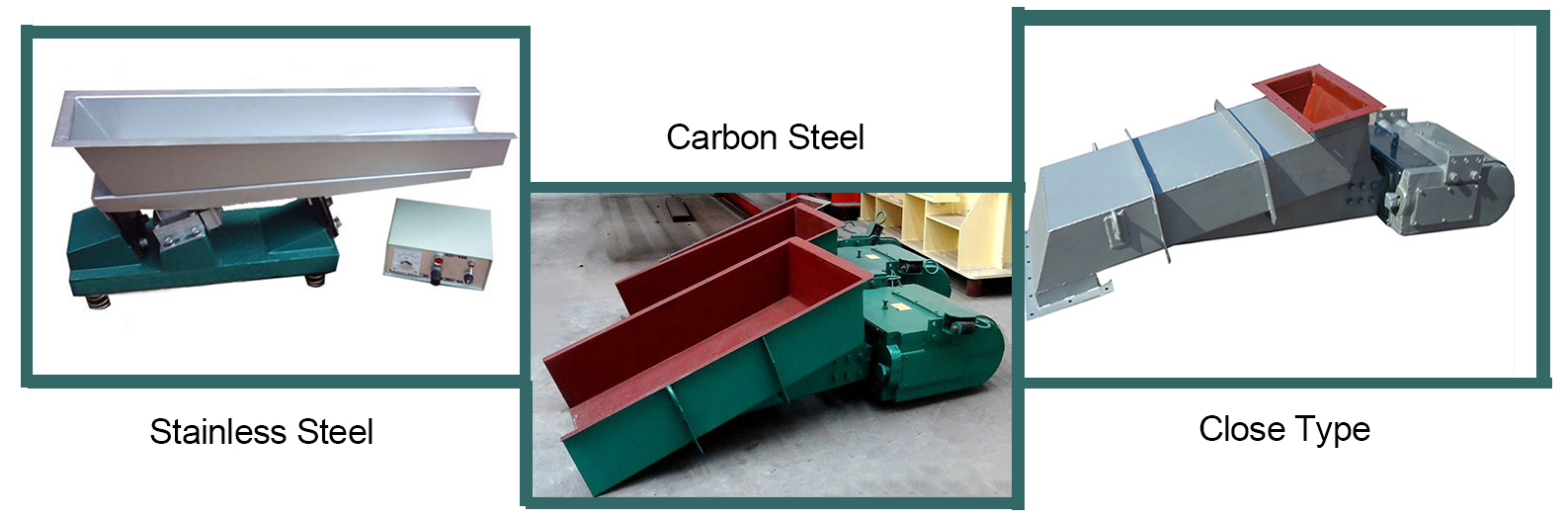

Mirant's Electromagnetic Vibrating Feeder is generally composed of trough, exciter, transmission device, etc. It adopts electromagnetic drive device to make the material reciprocate along the inclined direction. When the vertical component of the acceleration speed of the feeder exceeds the acceleration speed, the material is thrown upward and jumps in the form of a parabola. It only takes 1/5 second to rise and fall. The chute vibrates once and the material is thrown once. The chute vibrates at a frequency of 3000 times/minute. Correspondingly, the material is thrown upward and jumps forward. Make the material move forward continuously and evenly to achieve quantitative feeding. It can be selected from closed and open types.

1. Small size, light weight, less lubrication, easy maintenance, low operating cost.

2. Uniform feeding, good performance, stable vibration, long service life.

3. Closed structure, no dust pollution.

4. Intelligent design, less wear on the feed chute.

Mirant's Electromagnetic Vibrating Feeder is widely used in crushing and screening combined equipment in light industry, chemical industry, building materials, grain processing, mineral processing, electric power, food and other industries. In the predetermined processing process of powdery and granular materials, centralized and automatic control can be achieved.

Type | Model | Capacity(t/h) | Feeding Size (mm) | Amplitude (mm) | Frequency(r/m) | Voltage(V) | Current(A) | Active Power (kw) | Overall Weight (kg) | ||||

level | -10 | Working current | Token current | ||||||||||

Basic Type | ML1 | 5 | 7 | 50 | 1.75 | 3000 | 220 | 1.34 | 1.0 | 0.06 | 73 | ||

ML2 | 10 | 14 | 50 | 3.0 | 2.3 | 0.15 | 146 | ||||||

ML3 | 25 | 35 | 75 | 4.58 | 3.8 | 0.2 | 217 | ||||||

ML4 | 50 | 70 | 100 | 8.4 | 7 | 0.45 | 412 | ||||||

ML5 | 100 | 140 | 150 | 12.7 | 10.6 | 0.65 | 650 | ||||||

ML6 | 150 | 210 | 200 | 1.5 | 380 | 16.4 | 13.3 | 1.2 | 1250 | ||||

ML7 | 250 | 350 | 300 | 24.6 | 20 | 3 | 1900 | ||||||

ML8 | 400 | 560 | 300 | 39.4 | 32 | 4 | 3000 | ||||||

ML9 | 600 | 840 | 350 | 47.6 | 38.6 | 5.5 | 3200 | ||||||

ML10 | 750 | 1050 | 500 | 39.4*2 | 32*3 | 4*2 | 6000 | ||||||

ML11 | 1000 | 1400 | 500 | 17.6*2 | 38.6*2 | 5.5*2 | 7000 | ||||||

Q1: What's feeding material name? Bulk density (kg/m³)and water content (%)?

EM: Bulk, Granular, Powder materials.......

Q2: How much handing capacity of Electromagnetic vibration feeder as you want?

0.5t/h, 10t/h.....

Q3: What's local Voltage & Frequency in your city?

Various power voltage: 110V/200V/240V/380V/415V/450V/550V

Q4: What's material for machine as your need?

A. Stainless steel 304

B. Carbon Steel Q235

C. Touching parts SUS304