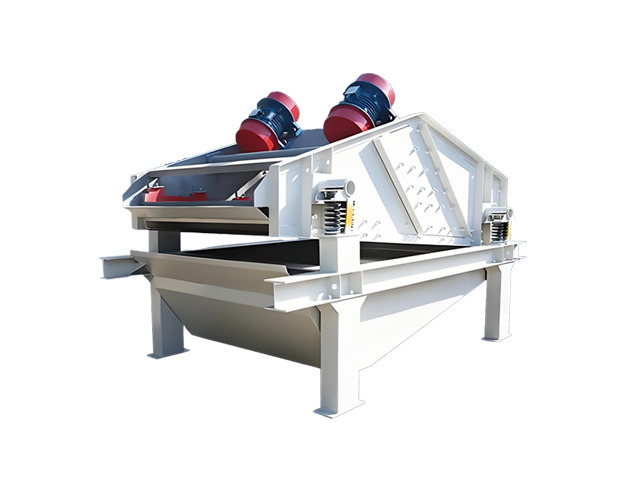

Mirant's Dewatering Screen is widely used in coal preparation, mineral processing, chemical industry, condiment and other industries to carry out dry and wet screening, dehydration, de-mediation and desludging of medium and fine particle materials.

It has the characteristics of reasonable structure, durability and convenient maintenance.

Mirant's Dewatering Screen adopts dual motor self-synchronization technology, universal eccentric block, and adjustable amplitude vibrator. It is mainly composed of screen box, vibrator, support system and motor. The two unconnected vibrators are driven by the belt coupling to run synchronously in the opposite direction. The centrifugal force generated by the two sets of eccentric masses is superimposed along the vibration direction, and the reverse centrifugal force is offset, thereby forming a single excitation vibration along the vibration direction, so that the screen box can perform reciprocating linear motion. The material is evenly fed into the dewatering screen inlet by the feed box (or cyclone). The water tension on the surface of the ore pulp is changed by the excitation force. The slurry water passes through the screen and becomes the underscreen material, while the fine material is blocked by the screen to form a filter layer and is affected by the vibration force to move forward and discharge.

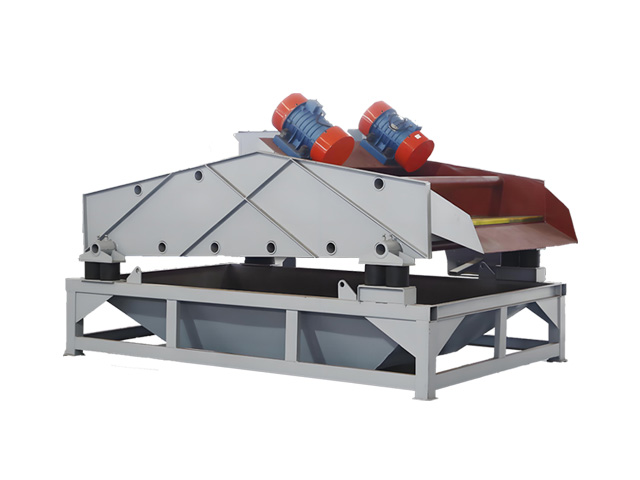

1. High working frequency, high vibration intensity, low moisture content of the product on the screen, and high processing capacity.

2. The power source uses a vibration motor, without bearings, couplings and other vulnerable parts, simple structure, easy installation and maintenance, low maintenance cost, and can work continuously for 24 hours.

3. The pre-dehydration screen plate is installed at a 45-degree angle to the horizontal, and the dehydration screen plate is installed at a negative angle to increase the dehydration area and promote the dehydration of the material as soon as possible to form a filter layer.

4. The side plate is connected to the crossbeam, motor seat and reinforcement plate with torsion shear type G strong bolts, without welds, to avoid the side plate cracking caused by welding.

5. The screen plate is made of polyurethane material with high opening rate and good water permeability.

6. The small screen machine uses rubber spring shock absorption, which has low noise, good shock absorption effect, and reduces the dynamic load of the screen machine on the foundation. The large screen machine uses high manganese steel springs with good elasticity.

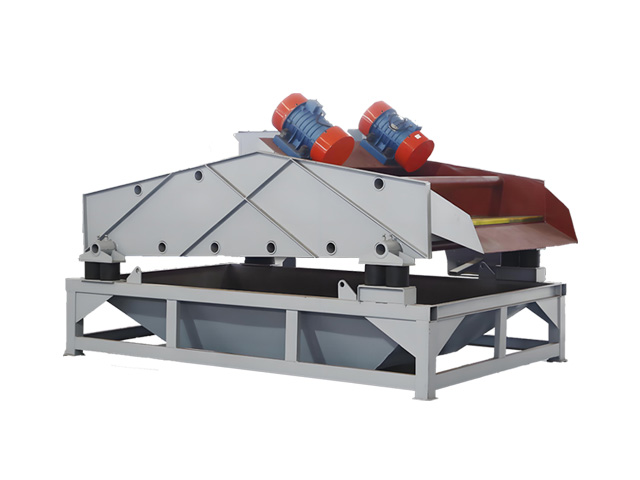

Mirant's Dewatering Screen is widely used in coal preparation, mineral processing, chemical industry, condiment and other industries for tailings dry discharge, water sand washing, coal slime dehydration, fine sand recovery, soil remediation, mud treatment, sewage treatment and other operations for medium and fine particle materials.

Dewatering and screening materials:

Iron tailings, gold tailings, copper tailings, vanadium tailings, lead-zinc tailings, graphite tailings, quartz sand, zircon sand, glass sand, building sand, foundry sand, building materials sand, potassium feldspar, etc.

Application treatment:

Urban sewage, industrial sewage, river sludge, coal slime dehydration, soil remediation, mud treatment, construction mud, drilling mud, etc.