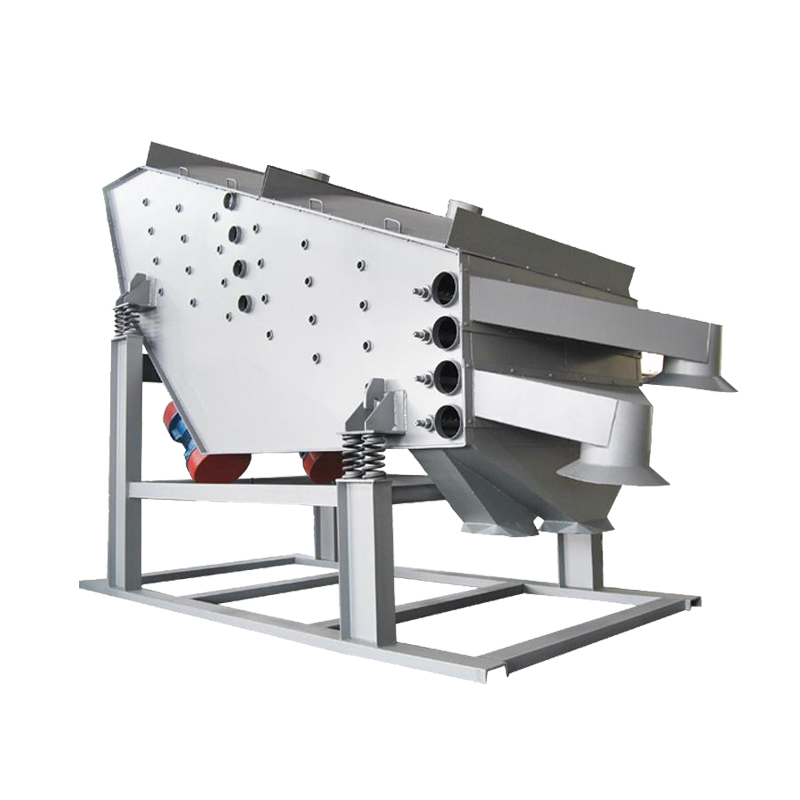

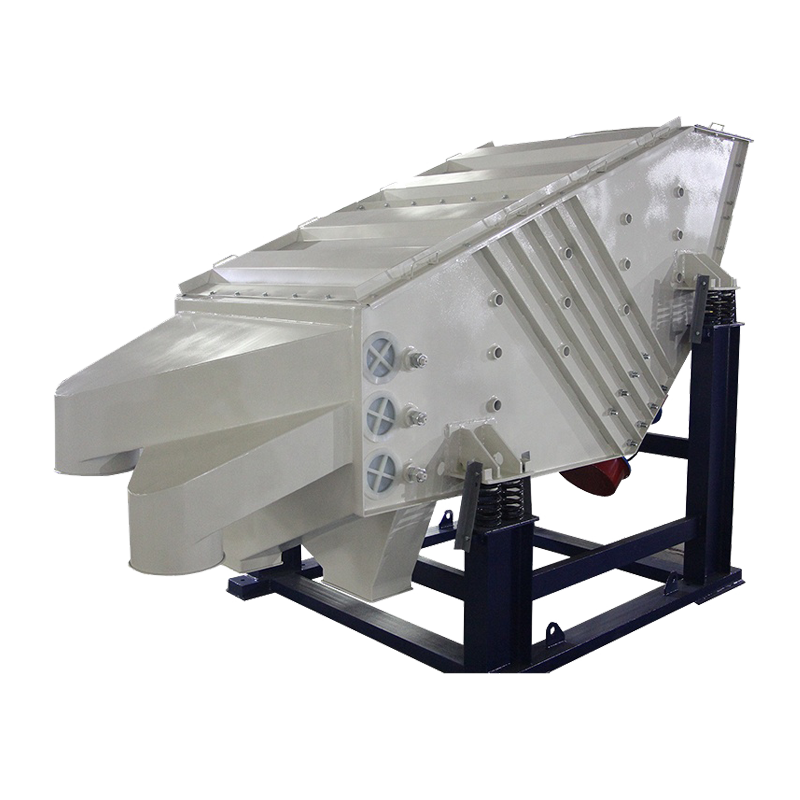

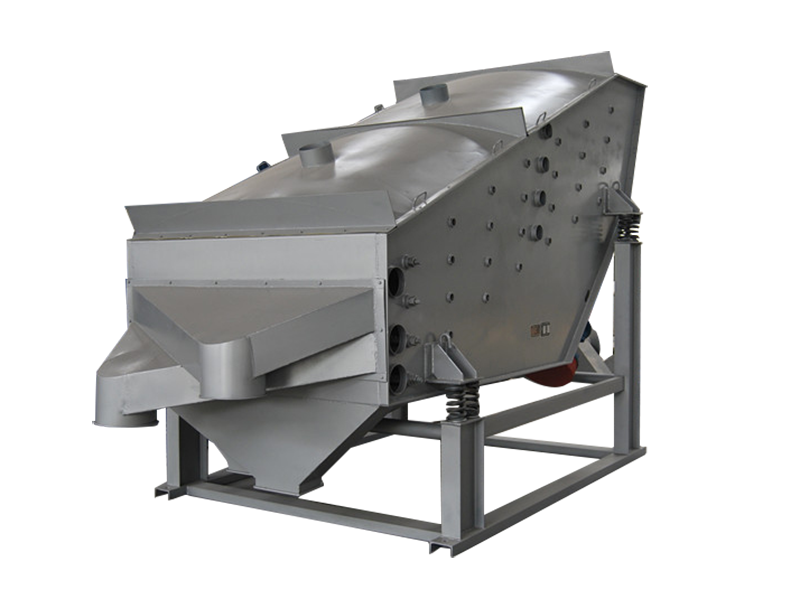

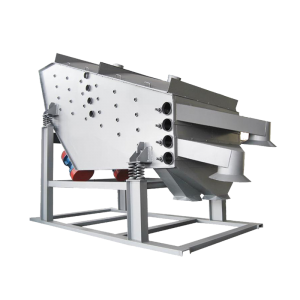

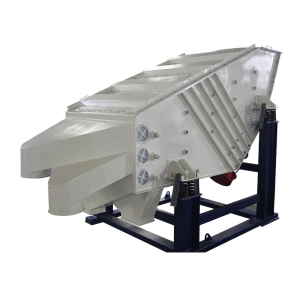

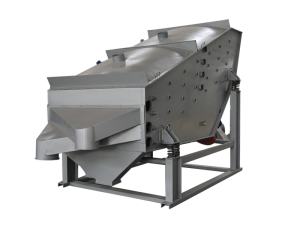

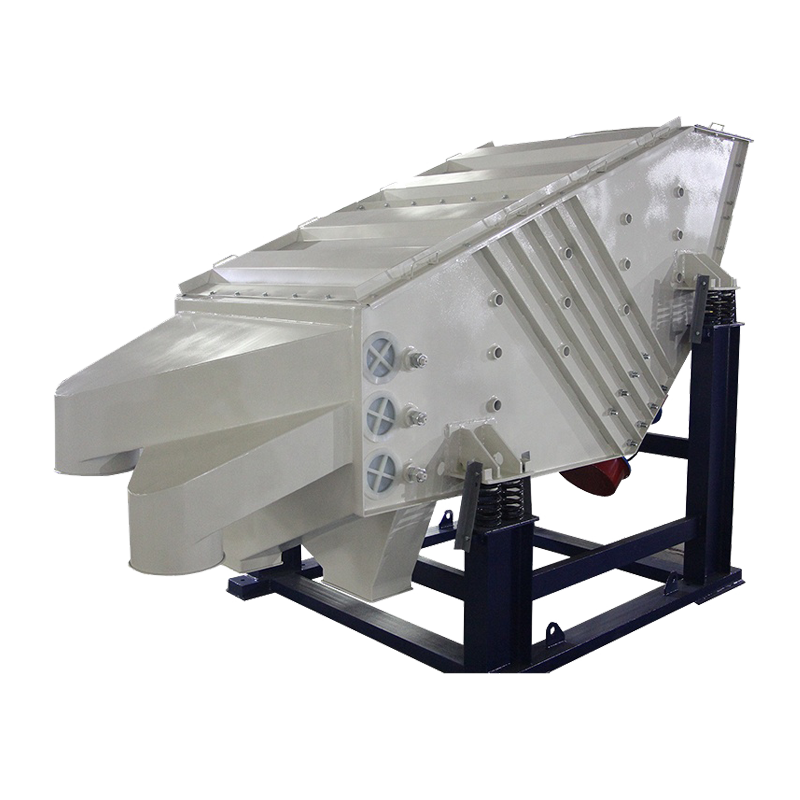

Mirant's Probability Screening is a kind of screening machine which can actively utilize the principle of probability screening. Generally speaking, the probabilistic screen is a vibration probabilistic screen whose screen surface is linearly vibrated by an exciting device. The main difference between the structure of the vibration probability screen and the flexible vibration screen is that the vibration probability screen adopts multi-layer (generally 3-6 layers), large inclination angle (generally 30-60 degrees), and large sieve hole (sieve hole size is 2-10 times the separation size).

1. Multi-stage classification.

2. High cost performance.

3. Unique and environment-friendly design.

4. Long life.

5. Lower noise.

6. Fast screening speed.

7. The screen hole is not easy to be blocked.

It has been sucessfully to metallurgical, building material and coal industries, the material size will be between from 10mm to 0.2mm.

Model | Sieve | Granule size (mm) | Driving motor | Frequency per min. | Double amplitude (mm) | Productivity (t/h) | |||||

Layers | Structure | Sieve hole (mm) | Screen area (㎡) | Screen angle(°) | Model | Power (kw) | |||||

GLS0615 | 2-8 | Woven mesh | 0-50 | 0.9 | 5-30 | ≤50 | YZS15-6 | 2×1.1 | 960 | 5-8 | 15-50 |

GLS0820 | 1.6 | YZS20-6 | 2×1.5 | 15-50 | |||||||

GLS1018 | 1.8 | YZS30-6 | 2×2.2 | 30-120 | |||||||

GLS1020 | 2.0 | YZS30-6 | 2×2.2 | 30-100 | |||||||

GLS1224 | 2.9 | YZS type vibration motor or Y series three-phase asynchronous motor | 2×2.30 | 30-100 | |||||||

GLS1521 | 3.2 | 2×3.7 | 30-100 | ||||||||

GLS1530

| 4.5 | 2×3.7 | 30-160 | ||||||||

GLS1620 | 3.2 | 2×3.7 | 30-160

| ||||||||

GLS1636 | 5.8 | 2×3.7 | 30-160 | ||||||||

GLS1630 | 5.4 | Y132M-6 | 2×5.5 | 30-180 | |||||||

GLS1845 | 8.1 | Y132M-6 | 2×5.5 | 30-180 | |||||||

GLS1830 | 6.0 | Y132M-6 | 2×7.5 | 50-200 | |||||||

GLS2045 | 9.0 | Y132M-6 | 2×7.5 | 50-200 | |||||||

GLS2048 | 10.1 | Y160L-6 | 2×11 | 50-200 | |||||||

Q1: How to solve the problem of blocking mesh?

All of most vibrating screen adopts bouncing ball and PU ring below every deck to cleaning screen surface, except the ultrasonic vibrating screen adopts ultrasonic cleaning systerm.

Q2: How to seal the machine?

Between two decks, it's adopt silica gel ring to seal. Then the clamp would lock two decks tightly with the extended copper nut.

Q3: Could this machine be refitted and designed technology to suit our production line?

Yes. All of machines in our factory could be customized by client's specific requirement such as the height from outlet to ground, the inlet shape & outlet shape, and the gate design on first deck. and the gate design on first deck.

Q4: How can i get the spare parts for machine?

The matched spares, such as seal ring, bouncing ball, screen plate, clamp screws and nut could be ordered one set or more as customer's need.

Or fill in the following blanks and let us know. Thanks~

1.the name of the material: _____

2.Material characteristics: (e.g. specific gravity, bulk density, water content, fluidity, adhesion, electrostatic properties, etc.)

3.Estimated processing capacity per hour:________(Kg/h)

4.How many layers do you need:_______

5.Mesh size of each layer needed:______ mesh/micron/mm

6.Voltage:______V, Frequency:______HZ, __ phase

7.Machine material will be: SS304/316L stainless steel or else?