Mirant's PP Plastic Vibration Screen is mainly used for screening and filtering of anti-corrosion powder material and liquid. It's also call polypropylene vibration sieve, PP Plastic vibration sieve, acid plastic vibration sieve, chemical vibration sieve etc.

It's very efficient for solving a difficult problem in Sieving Corrosive Material and ensure that the material will not deteriorate in the screening process.

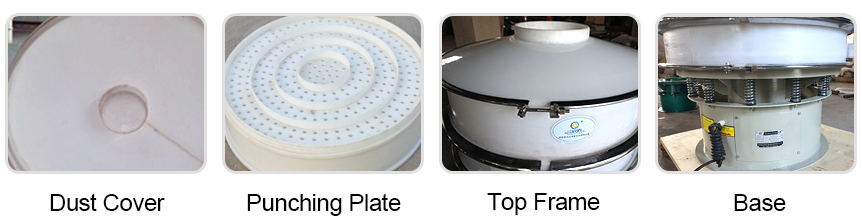

Mirant's PP Plastic Vibration Screen is designed as a high-precision screening machinery. it's adopts "vertical vibration motor" as the vibrator. On the top and bottom of the "vertical vibration motor" through installing eccentric hammer, make motor rotation movement into horizontal, vertical and tilted three dimensional movement. And then transfer the movement to the screen surface. Diameter can be ranged from 400mm to 2000mm, with single or multiple screening deck(1-5layer).

1. It can be used with single layer or multilayer mesh that can be graded and filtered from 2-4 levels at the same time.

2. Anti-clogging and self cleaning, it’s can be reduce the odds of blocking.

3. It's extremely suitable for screening and filtering corrosive material.

4. Continuous operation, automatic classification screening.

5. Usage long time and high efficiency, easy to change net.

6. Small volume, less space occupation, low weight.

7. Easy to move, 360 degree adjustment of discharge opening.

It has prominent advantages in solving material sieving problem such as material would produce chemical reaction when it contacted with metal.

| Model | Power | Sieve Diameter | Number of Layers | Granularity | Voltage | Throughput |

| (Kw) | (mm) | (Layer) | (mm) | (V) | (kg/h) | |

MLS-400 | 0.18 | 350 | 1-3 | <10 | 1140 | 100 |

| MLS-600 | 0.25 | 550 | 300-500 | |||

| MLS-800 | 0.55 | 750 | 500-800 | |||

| MLS-1000 | 0.75 | 920 | 900-1400 | |||

| MLS-1200 | 1.1 | 1120 | 1500-2100 | |||

| MLS-1500 | 1.5 | 1420 | 2100-2600 | |||

| MLS-1800 | 2.2 | 1720 | 2600-3300 |

1. Timely delivery with wooden cases.

2. Or standard exporting package (Non-fumigation) .

3. Or as your requirements.

4. Port: Shanghai port, Shenzhen port, Tianjin port and so on.

Q1: Why choose our machine?

A: Our company are specializing in all kinds of vibration screen more than 15 years. We have professional team to research and develop new and unique vibration.

Q2: What's raw material name? Bulk density (kg/m³) and water content(%)?

EM: Grain, Liquid, sand.......

Q3: How much mesh size do you want (mesh size of each layer)?

Single layer or Multi-lyayer is available. it's also can be customized by your requirements.

Q4: What's usually local power supply ______Voltage& ______Frequency in your city?

Various power voltage: 110V 200V 240V 380V 415V 450V 550V

Power Frequency: 50HZ 60HZ or Single phase electricity

Q5: What's material for machine do you need?

A Stainless steel 304

B Carbon steel Q235

C Touching parts SUS304

Q6: How do you ensure the quality of your products?

A: Generally, our equipments are the most durable type in the industry, this is also the feature of the label impression of the most of our customers at home or abroad.

Q7: How do your after-sale service work if the product got damaged?

A: During the maintenance period, our general after-sale service is changing the damaged parts for the customer. Normally, we will provide on-site guidance.