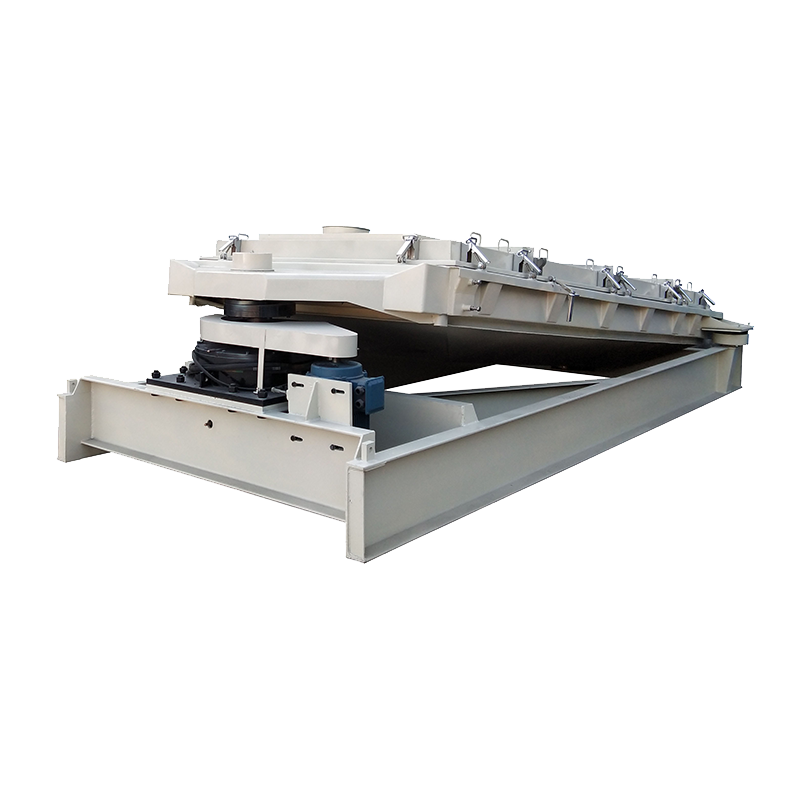

Gyratory Vibrating Screener (also call as Plane Rotary Screen) with high efficiency, meets large capacity and high-precision requirements, which is widely used in chemical, metallurgy, mining, feed, food and other industries, especially suitable for screening heavy alkali, salt, resin, fertilizer, urea particle size, feed, reduced iron powder, zirconium oxide, ceramics, barite and other materials.

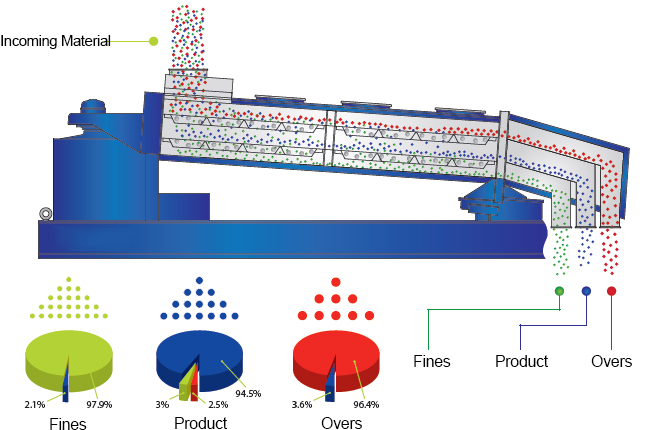

Gyratory Vibrating Screener (Flat Rotary Screen) is currently an effective screening machine that simulates the principle of artificial screening motion. It is mainly achieved by the movement of the eccentric machine. It is a uniform reciprocating rotary motion with an inclination angle of 3°-9°. Through the drive transmission chamber screen box, the material moves in a horizontal circle at the feed end, gradually becomes an elliptical motion in the length direction, and becomes an approximate reciprocating linear motion at the discharge end. After the material enters the screen body through the feed port, it can be evenly distributed on the screen surface of the compound vibrating screen under the action of inertial shaking force, and the material with smaller particle size under the material layer can quickly pass through the screen, while the material with larger particle size moves to the discharge end on the top, thereby achieving a high-efficiency and high-precision screening effect.

1. Good sealing, balance weight with less noise and good for enviromental protection.

2. Combination of circle, elliptic, linear motion, suitable for various material screening.

3. Automatic tension and self-cleaning system of the sieve net, long service life and high efficiency, and changing mesh conveniently.

4. Reinforced base ensurred more balanced operation, and with the adjustable hook if modification requested.

5. Improved wire rope hanging structure, avoiding wire wear.

6. 2 or 3 layers' screen frame design is optional.

7. For powder or granule feed screening and grade, for raw materials in feed factory grade, and for grade of intermediate products after second smashing.

Gyratory Vibrating Screener (Flat Rotary Screen) is widely used in metallurgy, refractory materials, sand and gravel, ceramsite sand, mining, chemistry, plastics, grain, food, chemical industry, biology, sugar making, salt making, MSG, starch, activated carbon, silicon carbide, soda ash, citric acid, medicine and other industries requiring large production capacity and high purity screening.

MODEL | FHS1020 | FHS1030 | FHS1224 | FHS1530 | FHS1536 | FHS1836 | FHS1840 | FHS2040 | FHS2050 |

Screen surface Length A(mm) | 3793 | 4835 | 4235 | 4875 | 5475 | 5275 | 5675 | 6755 | 6775 |

Height B(mm) | 1000 | 1200 | 1200 | 1200 | 1200 | 1200 | 1200 | 1300 | 1300 |

Width(mm) | 1408 | 1586 | 1796 | 2086 | 2086 | 2386 | 2386 | 2592 | 2592 |

Base width D(mm) | 1308 | 1456 | 1656 | 1956 | 1956 | 2256 | 2256 | 2480 | 2480 |

Mesh size(m) | 1.0*2.2 | 1.0*3.0 | 1.2*2.4 | 1.5*3.0 | 1.5*3.6 | 1.8*3.6 | 1.8*4.0 | 2.0*4.0 | 2.0*5.0 |

Screen area(㎡) | 2.2 | 3.0 | 2.88 | 4.5 | 5.4 | 6.48 | 7.2 | 8.0 | 1.0 |

No. of screen layers | 1-3 | 1-3 | 1-3 | 1-3 | 1-3 | 1-3 | 1-3 | 1-3 | 1-3 |

Voltage(v) | 380 | 380 | 380 | 380 | 380 | 380 | 380 | 380 | 380 |

Frequency(hz) | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 |

Power(kw) | 3.0 | 3.0 | 3.0 | 5.5-7.5 | 7.5 | 7.5 | 7.5 | 11 | 11 |

Rotation speed(s/min) | 960 | 960 | 960 | 960 | 960 | 960 | 960 | 960 | 960 |

Sieve stroke(mm) | 63 | 63 | 63 | 76 | 76 | 76 | 76 | 92 | 92 |

Rotation speed(s/min) | 196-200 | 196-200 | 196-200 | 196-200 | 196-200 | 196-200 | 196-200 | 196-200 | 196-200 |

Noise(DB) | <75 | <75 | <75 | <75 | <75 | <75 | <75 | <75 | <75 |

1. On-time delivery.

2. Certified standard or non-standard device accordingly.

3. Various packaging for transportation by truck, by sea or by air.

1. Technical suport.

2. Customized solution.

3. Accurate quotation.

4. OEM and so on.

1. 24 hours service online and quick response within 12 hours.

2. Regular maintenance and accessories supplying.

3. Provide assembly instruction, technical data or related videos.