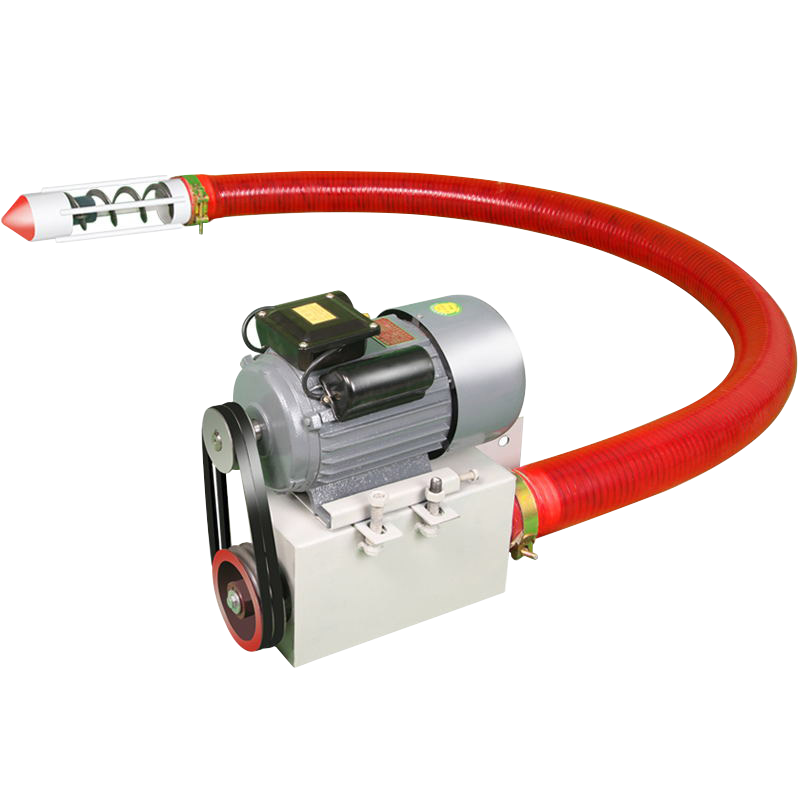

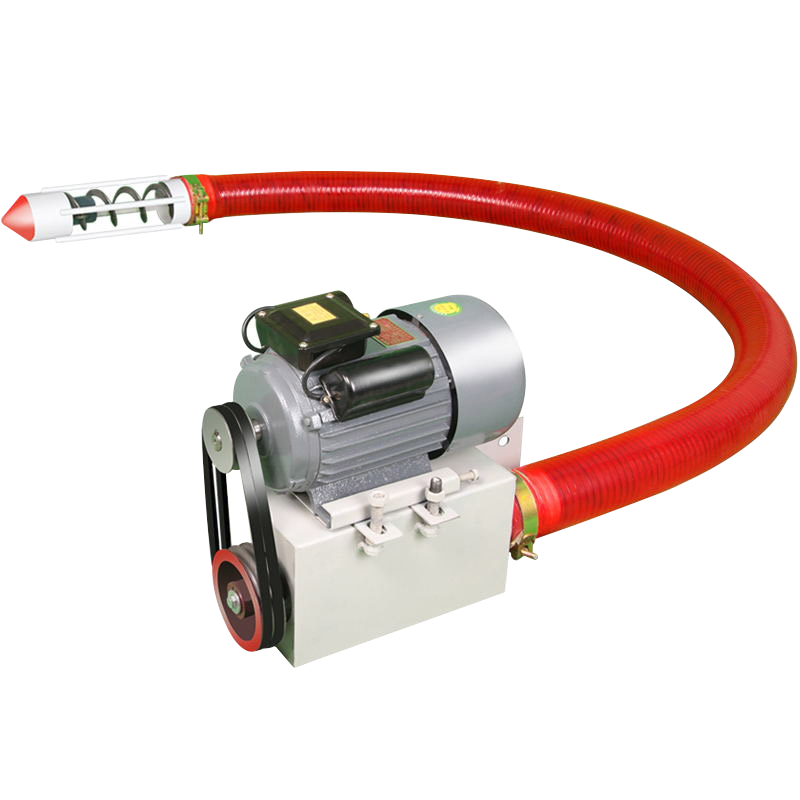

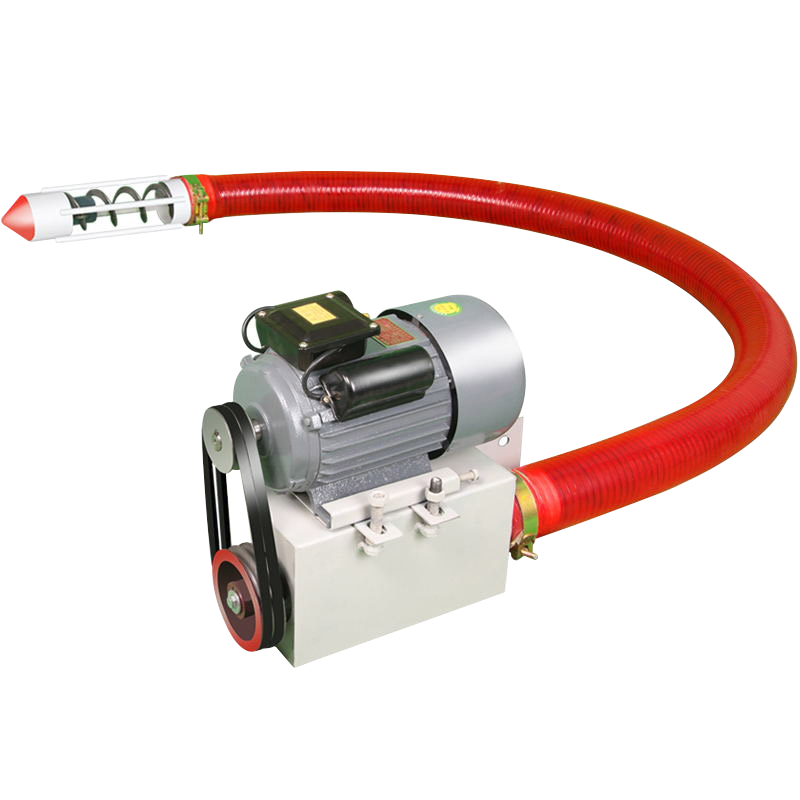

Mirant's Grain Suction Machine is a handy mini device designed for the loading and storage of transport grains, peanuts and other granular materials.

1. Small size, light weight, easy to move.

2. High grain absorption efficiency, saving labor

3. Safe and reliable, very suitable for self-employed households, grain farmers' cooperatives to transport wheat, soybeans, corn, rice, sorghum, paddy and other grains, and can also be used in farms, feed mills, food factories, plastic factories, etc. to transport plastics and resin particles.

4. It can be transported horizontally, tilted, and universally, with low transportation costs, changing the traditional transportation method and easy to use.

Mirant's Grain Suction Machine is suitable for bulk transportation, loading and unloading operations in the production process of docks and large grain warehouses.

Grain Suction Machine | ||||

ML-100 (240v/380v) | <6m | 6-8m | 8-10m | 10-12m |

3KW | 4KW | 4KW | 4.5kw | |

3.5KW | 3.5KW | 3.5KW | 3.5KW | |

ML-120 (240v/380v) | 4KW | 4.5KW | 4.5KW | 4.5KW |

3.5KW | 3.5KW | 3.5KW | 3.5KW | |

DY-160 380v | 4KW | 4KW | 4KW | 4KW |

1. Help high-end customer to choose a suitable machine and develop local market.

2. We can offer an accurate quotation according to customer's model or drawings.

3. The drawing can be send if needed, we can help you design the whole line based on your model.

4. OEM and label service will be always available.

1. 24 hours service online and fast response within 12 hours.

2. Quality warranty is 12 months from the shipping date.

3. Provide assembly instruction, technical date and related soft copies or video to ensure customer could install and debug by themselves.

FAQ:

Q1:WHow to solve the problem of blocking mesh?

All of most vibrating screen adopts bouncing ball and PU ring below every deck to cleaning screen surface,except the ultrasonic vibrating screen adopts ultrasonic cleaning systerm.

Q2:How to seal the machine?

Between two decks, it’s adopt silica gel ring to seal.Then the clamp would lock two decks tightly with the extended copper nut.

Q3:Could this machine be refitted and designed technology to suit our production line?

Yes.All of machines in our factory could be customized by client’s specific requirement such as the height from outlet to ground,the inlet shape&outlet shape,and the gate design on first deck.and the gate design on first deck.

Q4:How can i get the spare parts for machine?

The matched spares, such as dampling spring,Screen mesh,clamp screws and nut could be ordered one set or more as customer's need.