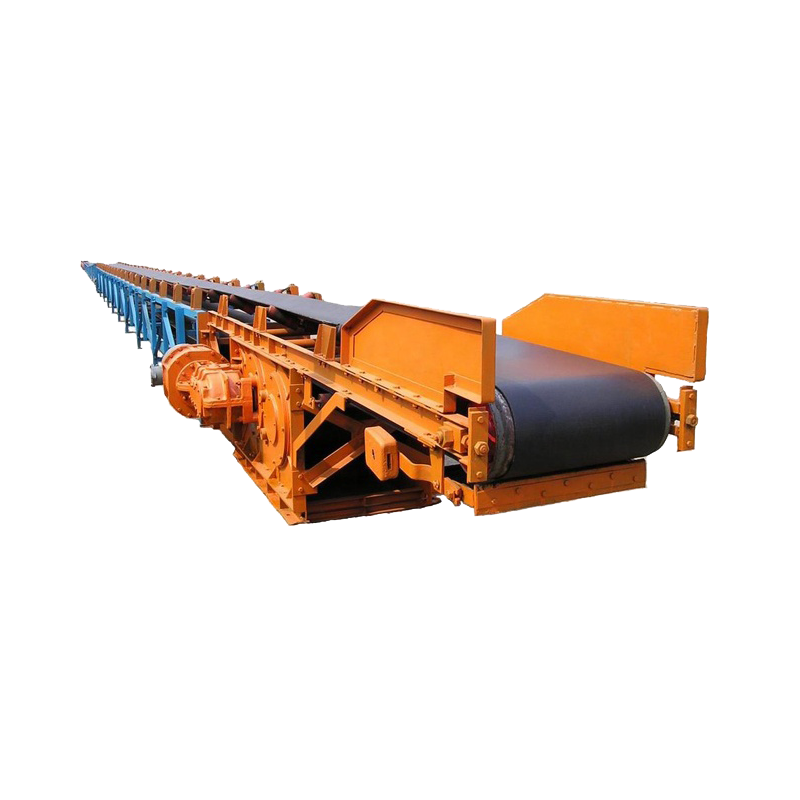

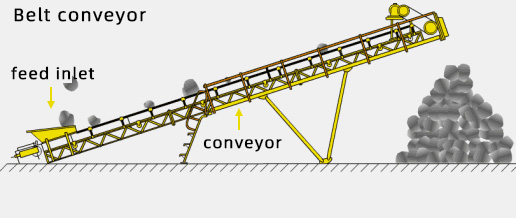

Mirant's Rubber Belt conveyor, also known as belt conveyor, with its conveyor belt moves according to the principle of friction transmission, is an ideal equipment for continuous conveying of bulk materials. It is widely used in underground mining engineering, chemical industry, building materials, metallurgy, electricity, light industry, food, ports and other industries.

It can convey various bulk materials (bulk density 0.5-2.5t/m³) in the working environment humidity range of -15℃℃-+40°C.

Mirant's Rubber Belt Conveyor is a kind of continuous conveying and loading and unloading equipment with high efficiency and good mobility. Belt conveyor is mainly used in places where the loading and unloading location changes frequently, such as: ports, docks, stations, coal yards, warehouses, construction sites, gravel yards, farms, etc., for short-distance transportation and loading and unloading of bulk materials or single-piece items weighing less than 100KG. It is divided into two categories: liftable and non-liftable. The operation of the conveyor belt is driven by an electric roller, and the lifting and operation of the whole machine are non-motorized.

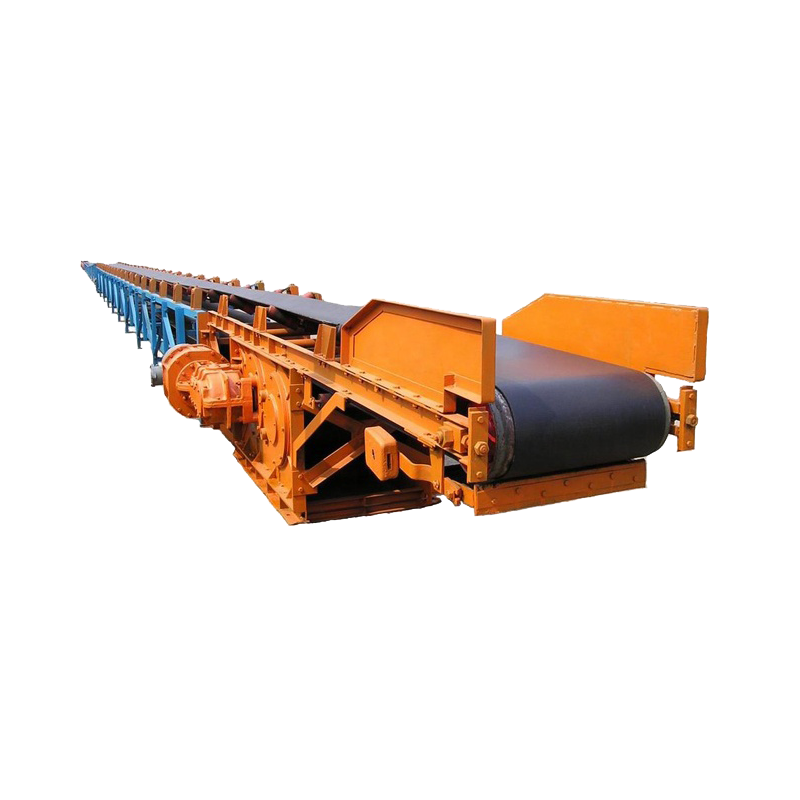

1. Reduce occupancy and save investment.

2. Large conveying capacity and strong versatility.

3. The inclination range is 0°~ 90°.

4. Simple structure, easy maintenance, and standardized parts.

Mirant's Rubber Belt Conveyor is ideal for the conveyance of a wide variety of free-flowing products such as snack foods, frozen foods, vegetables, fruits, candies, chemicals and other granules in the food, agriculture, pharmaceutical, cosmetics, chemical and other industries.

Belt width | Sidewall height | Cleat pitch | Slant angle | |||||

30° | 40° | 50° | 60° | 70° | 90° | |||

mm | mm | mm | Capacity(m³/h) Speed of belt=1m/s | |||||

500 | 120 | 252 | 52 | 40 | 32 | 26 | 21 | - |

160 | 378 | 65 | 52 | 42 | 34 | 28 | 17 | |

650 | 120 | 252 | 78 | 60 | 48 | 39 | 32 | - |

160 | 378 | 73 | 56 | 45 | 36 | 30 | - | |

800 | 120 | 129 | 99 | 76 | 60 | 49 | 40 | - |

200 | 378 | 148 | 114 | 91 | 74 | 61 | 37 | |

1000 | 160 | 378 | 129 | 99 | 79 | 64 | 52 | - |

240 | 504 | 229 | 176 | 141 | - | - | - | |

1200 | 160 | 252 | 223 | 180 | 144 | 117 | 96 | 59 |

240 | 378 | 342 | 280 | 224 | 183 | 149 | 91 | |

1400 | 200 | 252 | 299 | 231 | 185 | 151 | 123 | 75 |

240 | 378 | 422 | 345 | 276 | 225 | 184 | 113 | |

Q1: Why choose our machine?

A: Our company are specializing in all kinds of vibration screen more than 15 years. We have professional team to research and develop new and unique vibration.

Q2: What's raw material name? Bulk density (kg/m³)and water content (%)?

EM: Grain, Liquid, sand.......

Q3: May i ask the belt width, discharge height and ground length that you want?

The standard conveyor is with belt width 300mm, discharge height 3296mm.

Q4: Can you tell us if you need variable speed or only certain speed you need?

If you need variable speed, we shall add frequency inverter to control speed at any time as your need.

Q5: What's usually power ______Voltage ______Frequency in your city?

Various power voltage: 110V 200V 240V 380V 415V 450V 550V

Power Frequency: 50HZ 60HZ or Single phase electricity

Q6: How do you ensure the quality of your products?

A: Generally, our equipments are the most durable type in the industry, this is also the feature of the label impression of the most of our customers at home or abroad.

Q7: How do your after-sale service work if the product got damaged?

A: During the maintenance period, our general after-sale service is changing the damaged parts for the customer. Normally, we will provide on-site guidance.