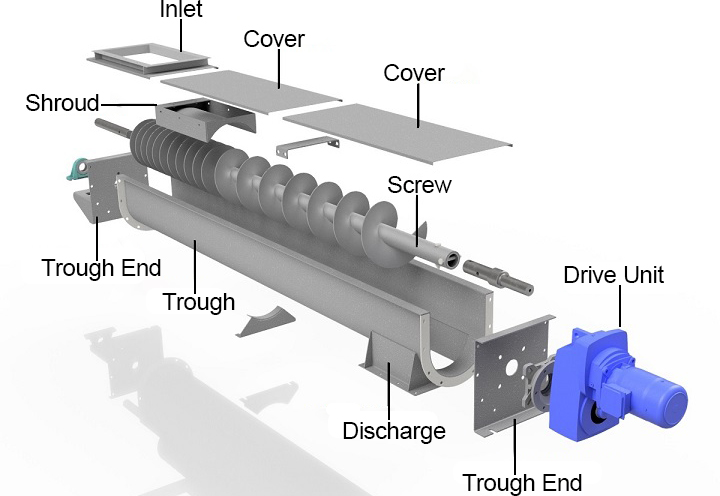

Mirant's Screw Conveyor consists of three parts: conveyor body, inlet and outlet devices and is mainly used to convey high-viscosity and high-compressibility materials and completes the mixing of materials during transportation.

It can be equipped with a single screen or multiple screens to achieve classification, impurity removal, dust removal, inspection, washing, material selection and dehydration, etc..

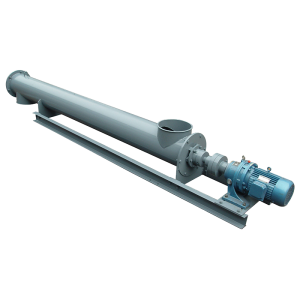

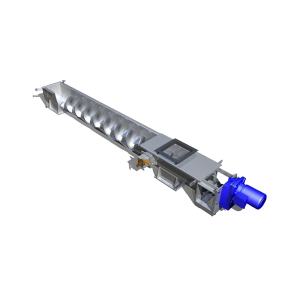

Mirant's Screw Conveyor, commonly known as auger, is a widely used conveying equipment in the mining, feed, grain and oil, and construction industries. Its operating principle is to use rotating spiral blades to push the conveyed materials along the fixed casing to carry out the conveying work.

1. Safe and reliable with large load-bearing capacity, .

2. Seamless steel pipe of the outer shell, and good rigidity and long service life of the flanges at both ends connected.

3. Good sealing, stable operation, easy installation, disassembly and replacement.

4. Equipped with a cleaning device on the discharge hole.

5. Low noise, few wearing parts needed, and without material blockage.

Mirant's Screw Conveyor is widely used in different industries such as building materials, chemicals, electricity, metallurgy, coal and food, and is used for horizontal or oblique conveying of powdered, granular, and small block materials, such as coal, fly ash, slag cement, and food.etc.

There are two types of Mirant's Screw Conveyor in terms of conveying form——Shaft Screw Conveyor and Shaftless Screw Conveyor, and are two types in terms of appearance——U-shaped Screw Conveyor and Tubular Screw Conveyor. Shaft Screw Conveyor is suitable for non-sticky dry powder materials and small particle materials (such as cement, fly ash, lime, grain, etc.), while Shaftless Screw Conveyor is suitable for conveying sticky and easily entangled materials (such as sludge, biomass, garbage, etc.).

LS | 100 | 160 | 200 | 250 | 315 | 400 | 500 | 630 | 800 | 1000 | 1250 |

GX | 200 | 250 | 300 | 400 | 500 | ||||||

Dimater (mm) | 100 | 160 | 200 | 250 | 315 | 400 | 500 | 630 | 800 | 1000 | 1250 |

Screw Pitch (mm) | 100 | 160 | 200 | 250 | 315 | 355 | 400 | 450 | 500 | 560 | 630 |

Speed (r/min) | 140 | 120 | 90 | 90 | 75 | 75 | 60 | 60 | 45 | 35 | 30 |

Capacity QΦ=0.33(m³/h) | 2.2 | 7.6 | 11 | 22 | 36.4 | 66.1 | 13.1 | 160 | 223 | 304 | 458 |

Power Pd 1=10m(kw) | 1.1 | 1.5 | 2.2 | 2.4 | 3.2 | 5.1 | 4.1 | 8.6 | 12 | 16 | 24.4 |

Power Pd 1=30m(kw) | 1.6 | 2.8 | 3.2 | 5.3 | 8.4 | 11 | 15.3 | 25.9 | 36 | 48 | 73.3 |

Speed (r/min) | 120 | 90 | 75 | 75 | 60 | 60 | 45 | 45 | 35 | 30 | 20 |

Capacity QΦ=0.33(m³) | 1.9 | 5.7 | 18 | 18 | 29.1 | 52.9 | 69.8 | 125 | 174 | 261 | 305 |

Power Pd 1=10m(kw) | 1.0 | 1.3 | 2.1 | 2.1 | 2.9 | 4.1 | 4.7 | 6.8 | 9.4 | 14.1 | 16.5 |

Power Pd 1=30m(kw) | 1.5 | 2.3 | 4.5 | 4.5 | 7 | 8.9 | 11.6 | 20.4 | 28.3 | 42.2 | 49.5 |

Speed (r/min) | 90 | 75 | 60 | 60 | 45 | 45 | 35 | 35 | 30 | 20 | 16 |

Capacity QΦ=0.33(m³/h) | 1.4 | 4.8 | 15 | 15 | 21.8 | 39.6 | 54.3 | 97 | 149 | 174 | 244 |

Power Pd 1=10m(kw) | 0.9 | 1.2 | 1.9 | 1.9 | 2.5 | 3.4 | 4.3 | 5.4 | 8.1 | 9.5 | 13.3 |

Power Pd 1=30m(kw) | 1.2 | 2.2 | 3.8 | 3.8 | 5.4 | 6.8 | 9.2 | 16 | 24.4 | 28.6 | 39.9 |

Speed (r/min) | 75 | 60 | 45 | 45 | 35 | 35 | 30 | 30 | 20 | 16 | 13 |

Capacity QΦ=0.33(m³/h) | 1.2 | 3.8 | 11 | 11 | 17 | 31.7 | 46.5 | 73.0 | 99.3 | 139 | 199 |

Power Pd 1=10m(kw) | 0.75 | 1.1 | 1.6 | 1.6 | 2.1 | 3.1 | 3.7 | 4.6 | 5.7 | 7.7 | 11 |

Power Pd 1=30m(kw) | 1.1 | 1.8 | 3.4 | 3.4 | 4.4 | 5.6 | 8 | 14 | 16.7 | 23.2 | 33 |

Note

We can design and manufacture unstandard models and specifications of screening machines according to your need.

We reserves the right to modify all technical data and dimensions. If the actual product doesn't match the data, the actual product shall prevail.

Screw Conveyor is suitable for working enviroment temperature which is between 20℃to 50 ℃; Including the horizontal screw conveyor, temperature of material conveyed should be lower than 200℃; Conveying distance less than 40 meters, maximum not exceeding 70 meters; Vertical screw conveyor, it's temperature should not be more 80 ℃, the vertical hight is not more than 8 meters.

Selection Model: LS Type screw conveyor can according to different customers production situation and production purpose to customize. production material could be all carbon steel, stone stainless steel, or all stainless steel, With food hygiene requirements of enterprise recommend stainless steel material, no request can use carbon steel.

1. Help high-end customer to choose suitable machine and develop local market.

2. Accurate quotation according to customer's model or drawings.

3. The drawing can be send if needed, we can help you design the whole line based on your model.

4. OEM and label service.

1. 24 hours service online.

2. Quality warranty.

3. Provide assembly instruction, technical date and related soft copies or video to ensure customer could install and debug by themselves.

Q1: What's material do you want by screw conveyor?

Cement, sand, limestone and grain etc.

Q2: What's capacity of screw conveyor do you want?

EM: 20t/h, 50t/h, 100t/h Etc.

Q3: What's color of screw conveyor do you need?

The machine color can be customized by you required.

Q4: It's better if you have layout drawing or sketch?

We can re-made new products as your sketch picture.