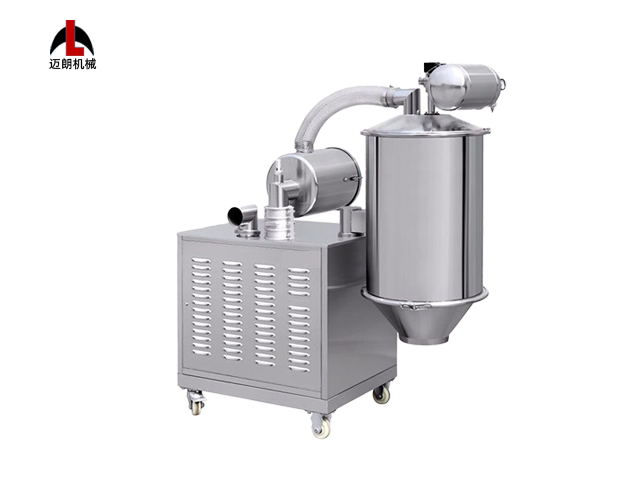

Mirant's Vacuum Loader is a vacuum feeding machine by using pneumatic pump as vacuum source. it has advantages of fast feeding, long service period, operation, clean and healthy and in conformity with GMP requirement.

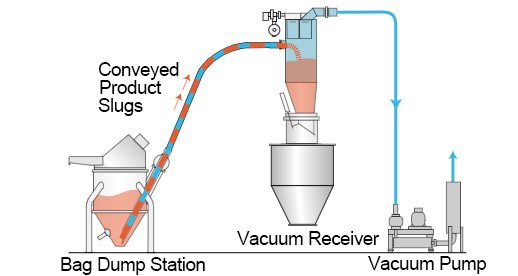

When compressed air is supplied to the vacuum generator, the vacuum generator generates negative pressure to form a vacuum airflow, and the material is sucked into the suction nozzle to form a material airflow, which passes through the suction pipe to reach the hopper of the feeder. The filter completely separates the material from the air. When the material fills the hopper, the controller will automatically cut off the air supply, the vacuum generator stops working, and the hopper door automatically opens, and the material falls into the hopper of the equipment. At the same time, the compressed air automatically cleans the filter through the pulse backflush valve. When the time is up or the material level sensor sends a feeding signal, the feeder is automatically started.

1. Material can be customized by stainless steel SUS304 or SUS316 to meet GMP standard.

2. It's completely sealed for dust-free working condition.

3. This vacuum conveyor can feed powder or small granule product into sealed or open containers.

4. The machine boy is compact, reliable and operation is very easy.

Mirant's Vacuum Loader is used as automatic feeding equipment for packaging machines, mixers, tablet presses, vibrating screens, capsule filling machines, wet granulators, packaging machines, crushers and other machines. It is widely used in food industry, pharmaceutical industry, metallurgy industry, chemical industry and other industries.

Flavors, spices, MSG, adsorbents, catalysts, graphite, rouge, blush, polyethylene, polypropylene, polyoxyethylene, fertilizers, veterinary drugs, feed, premixes, additives, washing powder, salt, MSG, chicken essence, sugar, seeds and other products can be applied.

| Model | ZKS-2 | ZKS-3 | ZKS-4 | ZKS-5 | ZKS-6 | ZKS-7 |

| Capacity | 600L/h | 1200L/h | 2000L/h | 3000L/h | 4000L/h | 6000L/h |

| Power | 2.2Kw | 3.0Kw | 4.0Kw | 5.5Kw | 5.5Kw | 7.5Kw |

Gas consumption | 8L/min | 10L/min | 12L/min | 12L/min | 12L/min | 12L/min |

Gas supply pressure | 0.5-0.6mpa | 0.5-0.6mpa | 0.5-0.6mpa | 0.5-0.6mpa | 0.5-0.6mpa | 0.5-0.6mpa |

| Dimensions | ∅290x996 | ∅290x996 | ∅420x1328 | ∅420x1328 | ∅420x1328 | ∅420x1420 |

(Remark: Production rate is measured by material volume of 1.3ton/m³)

1. Help high-end customer to choose a suitable machine and develop local market.

2. We can offer an accurate quotation according to customer's model or drawings.

3. The drawing can be send if needed, we can help you design the whole line based on your model.

4. OEM and label service will be always available.

1. 24 hours service online and fast response within 12 hours.

2. Quality warranty is 12 months from the shipping date.

3. Provide assembly instruction, technical date and related soft copies or video to ensure customer could install and debug by themselves.