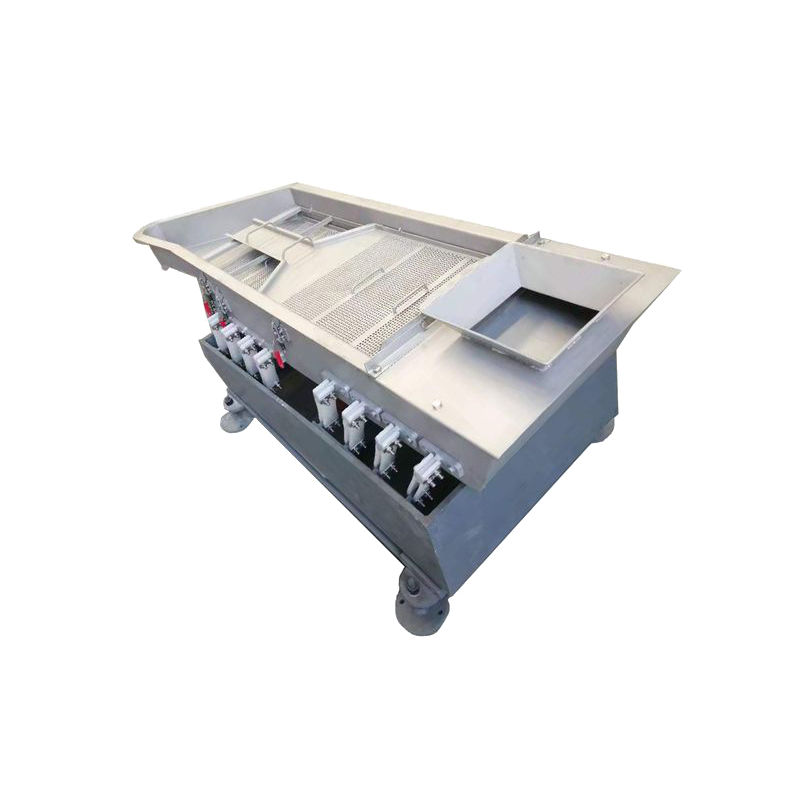

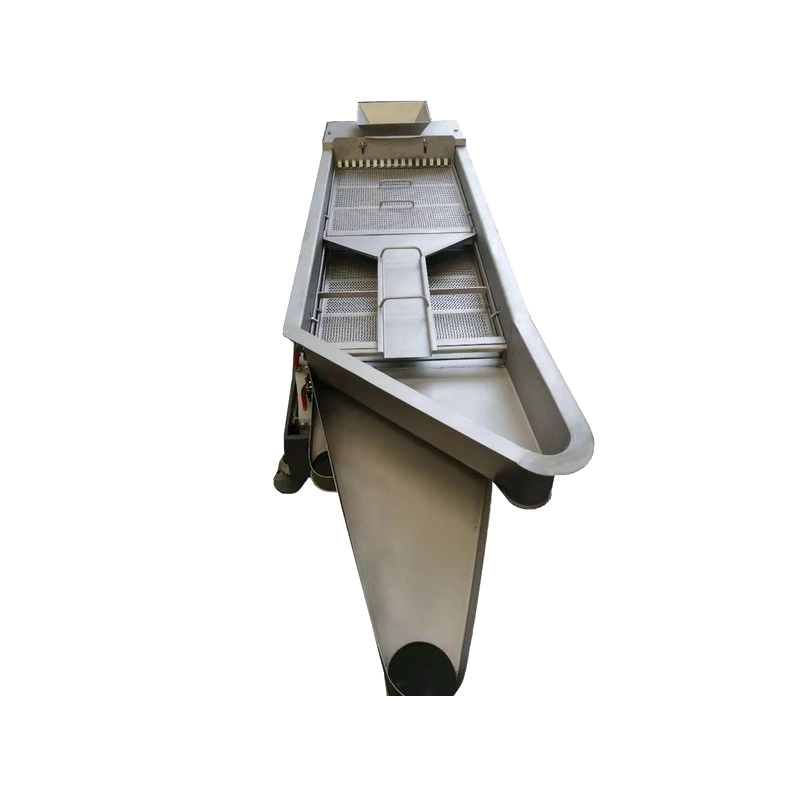

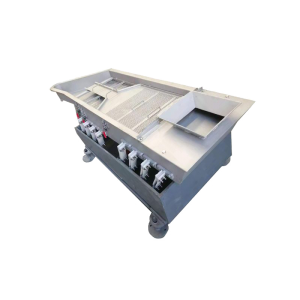

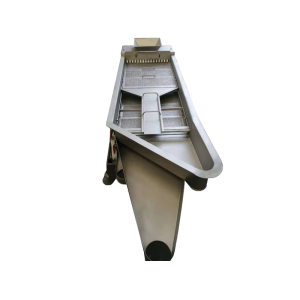

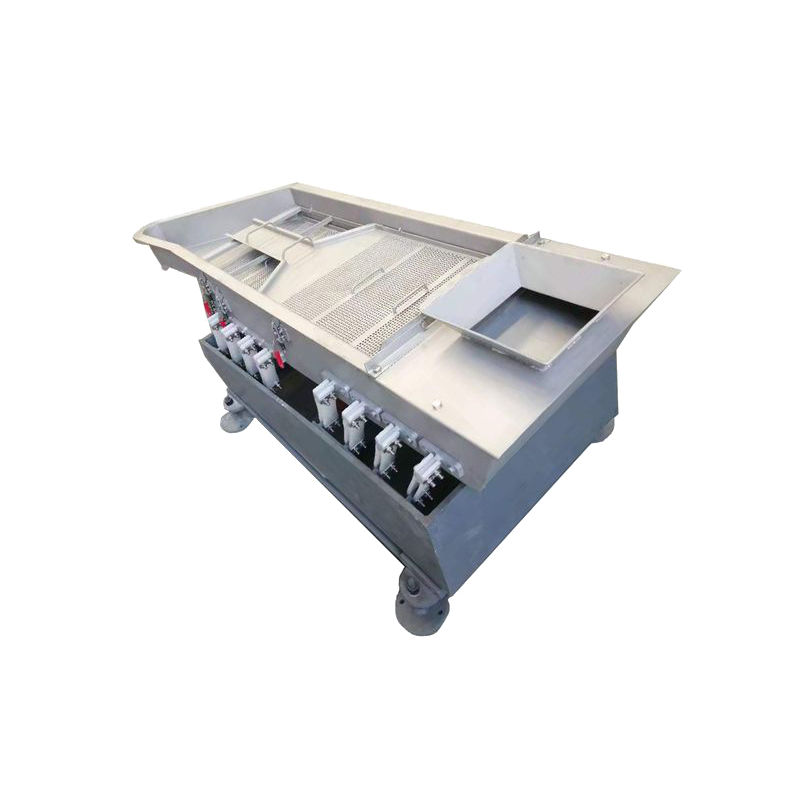

Mirant's Reciprocating Vibrating Screen is a new type of vibrating screen with reasonable design, simple structure, stable operation. It is equipped with anti-blocking net and anti-sticking net. Fixed on the ground, it runs very smoothly with little noise.

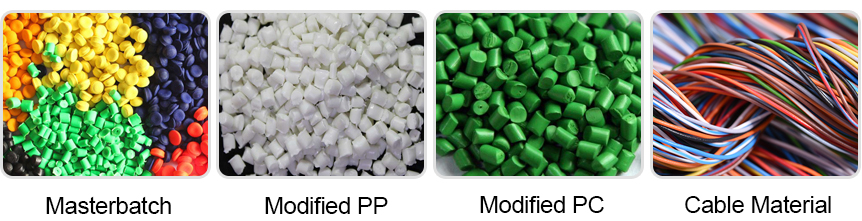

The Reciprocating Vibrating Screen is widely used in various masterbatches, engineering plastics and rubber materials. With the characteristics of low energy consumption, high output, simple structure, easy maintenance, automatic discharge, etc., it is more suitable for assembly line operation.

Mirant's Reciprocating Vibrating Screen uses vibration motor to generate the excitation force to drive the screen surface support base to vibrate at a certain angle, which then drives the screen surface connected to the base to vibrate in the form of resonance. The screen surface is supported by a flat spring structure to ensure that the screen surface always vibrates in the horizontal direction.

It has a similar structure to the linear vibrating screen. The ordinary spring is replaced with a number of spring plates. The vibration motor is placed at the bottom of the screen body. Under the action of the vibration motor, the screen body reciprocates back and forth. The material moves from the inlet to the outlet on the screen surface and is screened through the sieve holes.

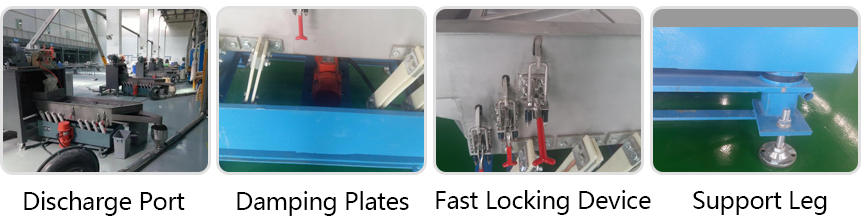

1. A double-body resonance structure:

Smooth reciprocating swing at the natural frequency, being obviously different from the traditional forced direct vibration transmission method with no disordered excitation in the box, withstanding long-term vibration without cracking.

2. Stable and adjustable vibration speed and amplitude:

Material can be smoothly transferred on the screen surface under the optimal operating parameters without long particle bouncing and leaking basically.

3. Quantifying the screening rate:

The screening efficiency of 3 times the particle length is more than 98%.

4. High screening accuracy:

Three-layer composite screen surface structure with 3 times screening screened.

5. Screening various sizes of screening objects with high efficiency:

Up to 10 different screen holes (round holes, long holes, etc.) of 2-10mm's dia., and switching flexibly.

6. Less noise:

Small dynamic load on the foundation.

Screening and impurity removal:

PUA particles, round and oval plastic particles;

Powder and granular materials in chemical, medical and other industries.

Screening of raw materials and finished products:

Grain, heavy alkali, large granular urea, small granular urea, ceramsite, zirconium oxide, reduced iron titanium powder, barite, food and spices, chemicals, plastics, mining, rubber, wood and plywood, medicine, sugar, mining, papermaking, etc.

Model | Length(mm) | Width(mm) | Height(mm) | Motor Powder(kw) | Noise(dB) |

SPX05 | 2300 | 785 | 1000 | 0.25*1 | 50 |

SPX06 | 2300 | 1160 | 1000 | 0.16*2 | 50 |

SPX07 | 2800 | 1260 | 1000 | 0.25*2 | 50 |

Q1: What's material you expect to sieve?

Is it dry, what is the size of feed material?

Q2: How much capacity do you expect (kg/h)?

EM: 200kg/h

Q3: What's the materila of machine?

Usually we use Stainless steel 304, if you want Stainless steel 316, it's okay and please tell us.

Q4: What's usually power ______Voltage______Frequency in your city?

For example, 380V 50Hz 3p; 440V 60Hz 3p; 220V.....etc.

(We only provide 3P, because our machine are all for industrial use, not for family.)

Q5: How do you ensure the quality of your products?

A: Generally, our equipments are the most durable type in the industry, this is also the feature of the label impression of the most of our customers at home or abroad.

Q6: How do your after-sale service work if the product got damaged?

A: During the maintenance period , our general after-sale service is changing the damaged parts for the customer. Normally, we will provide on-site guidance.