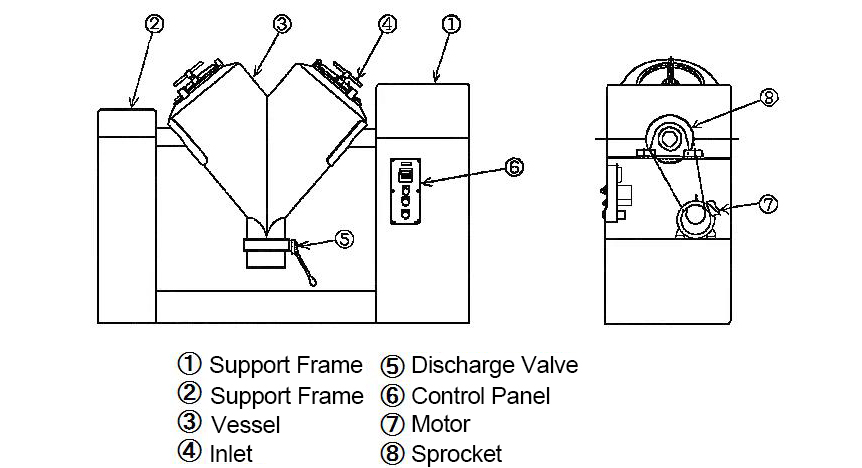

Mirant's V Type Mixer is a device that mechanically drives two or more high-quality V-shaped cylinders to reciprocate and mix two or more materials through mechanical force and gravity. It consists of a cylinder, a transmission shaft, a bracket, etc. The cylinder is connected to the transmission shaft, and the transmission shaft drives the cylinder to rotate. The material is repeatedly sheared, diffused, and dislocated in the cylinder, and finally achieves uniform mixing.

Mirant's V Type Mixer is a device that mechanically drives two or more high-quality V-shaped cylinders to reciprocate and mix two or more materials through mechanical force and gravity. It consists of a cylinder, a transmission shaft, a bracket, etc. The cylinder is connected to the transmission shaft, and the transmission shaft drives the cylinder to rotate. The material is repeatedly sheared, diffused, and dislocated in the cylinder, and finally achieves uniform mixing.

A motor and a reducer are installed at one end of the V Type Mixer. The motor power is transmitted to the reducer through a belt, and then to the V-type barrel through a coupling. The V-type barrel runs continuously, driving the materials in the barrel to mix up, down, left and right in the barrel.

It is suitable for mixing powders and granules with good fluidity and small differences in physical properties, as well as for mixing materials with low mixing requirements but short mixing time. Since the materials in the V-type mixing container flow smoothly and will not destroy the original shape of the materials, the V Type Mixer is also suitable for mixing granular materials that are easy to break and wear, or for mixing finer powders, blocks, and materials containing a certain amount of water. It is widely used in the pharmaceutical, chemical, food and other industries.

The machine has a reasonable and simple structure, closed operation, convenient feeding and discharging (manual or vacuum feeding), and the barrel is made of stainless steel for easy cleaning.

1. The machine barrel has no dead corners, no material accumulation, and short mixing time.

2. The barrel is made of stainless steel, with polished inner and outer walls, beautiful appearance and easy to clean.

3. The feeding can be manual or vacuum feeding, and the rotary valve and rotary cap are used for discharge.

4. Equipped with a timer, the mixing time can be adjusted at will.

5. Low noise and no vibration.

Mirant's V Type Mixer is widely used in mixing powder or granular materials in chemical, food, medicine, feed, ceramics, metallurgy and other industries.

Model | Volume(L) | Voltage(V) | Rotating Speed(r/min) | Size(mm) | Weight |

VH-20 | 20 | 220 | 0.25 | 500x250x490 | 45 |

VH-50 | 50 | 380 | 0.375 | 1150x500x750 | 95 |

VH-100 | 100 | 0.75 | 1800x650x1300 | 140 | |

VH-150 | 150 | 1.1 | 1900x700x1400 | 230 | |

VH-300 | 300 | 1.5 | 2320x800x1470 | 330 | |

VH-500 | 500 | 2.2 | 2520x900x1510 | 550 | |

VH-1000 | 1000 | 3 | 3040x1000x1765 | 1000 |

Q1: What's material you expect to grind?

Is it dry, what is the size of feed material?

Q2: How much capacity do you expect (kg/h)?

EM: 200kg/h

Q3: What's the materila of machine?

Usually we use Stainless steel 304, if you want Stainless steel 316, it's okay and please tell us.

Q4: What's usually power ______Voltage ______Frequency in your city?

For example, 380V 50Hz 3p; 440V 60Hz 3p; 220V.....etc.

(We only provide 3P, because our machine are all for industrial use, not for family)

Q5: How do you ensure the quality of your products?

A: Generally, our equipments are the most durable type in the industry, this is also the feature of the label impression of the most of our customers at home or abroad.

Q6: How do your after-sale service work if the product got damaged?

A: During the maintenance period, our general after-sale service is changing the damaged parts for the customer. Normally, we will provide on-site guidance.