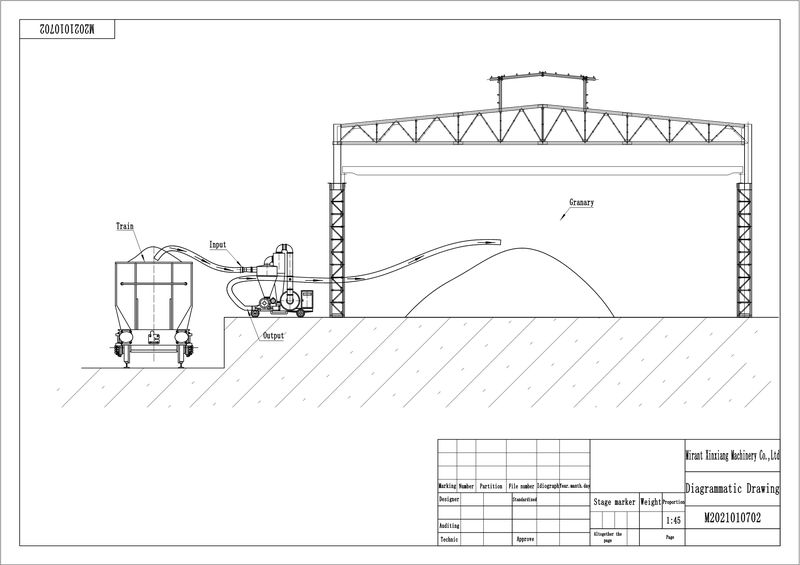

Mirant's Grain Pneumatic Conveyor is specially designed and developed.It's very convenient for bulk grain dumping, clearing,loading and unloading methods for flour mills, grain stroage deports and other departments.Users need to adopted models powered by diesel engines.

It can convey by positive pressure separate or suction by vacuum separate or convey by positive and vacuum pressure at same time after a simple combination and can be used to convey granular material on horizontl and vertical such as soybean, rice, wheat, corn, sorghum, barley malt, plastics and resins etc.

The negative pressure airflow generated by high pressure is blown in through the suction nozzle to suck the material into the hose. The material passes through the separation pipe, the air and the material are separated, and the material falls downward into the air lock. The positive pressure airflow then transports the material to the desired location. The separated air enters the feeder through the separation pipe or dust collector.

1. Good dust-proof effect.

2. Easy to realize machaniztion and automation.

3. Reduce labor intensity and save manpower.

4. The whole machine has low noise and quite agilit.

5. High efficiency and energy saving.

6. Easy to conveying material and recycle.

Mirant's Grain Pneumatic Conveyor is suitable for horizontal, inclined and vertical conveying of granular materials such as soybeans, rice, wheat, corn, sorghum, barley malt, plastics, resins, etc.

Model | ML-05 | ML-10 | ML-15 | ML-20 | ML-25 | ML-30 | ML-50 |

Fan power(kw) | 7.5 | 11 | 15 | 22 | 25 | 37 | 55 |

Air-lock valve(kw) | 0.75 | 0.75 | 1.1 | 1.1 | 1.5 | 1.5 | 1.5 |

Power(kw) | 8.25 | 11.75 | 16.1 | 23.1 | 26.5 | 38.5 | 56.5 |

Air flow(m³/h) | 800 | 1000 | 1600 | 1800 | 1800 | 1800 | 2100 |

Fan pressure(mmH20) | 1500 | 1500 | 1600 | 2200 | 2400 | 3300 | 4400 |

Max horizontal distance(m) | 30 | 50 | 70 | 100 | 100 | 140 | 200 |

Conveying distance(m) | 3 | 10 | 15 | 20 | 20 | 30 | 80 |

Lift head(m) | 5 | 12 | 18 | 20 | 20 | 30 | 42 |

Capacity(t) | 5 | 10 | 20 | 30 | 23 | 50 | 78 |

Feeding dia(mm) | 124 | 150 | 150 | 160 | 160 | 160 | 200 |

Discarging dia(mm) | 100 | 124 | 150 | 160 | 160 | 160 | 200 |

Q1:How do you ensure the quality of your products?

Generally, our equipments are the most durable type in the industry, this is also the feature of the label impression of the most of our customers at home or abroad.

Q2: How do your after-sale service work if the product got damaged?

1Service process,We can do pre-sale,-sale,after-sale service.

2. In the equipment installation and commissioning and process in the use of special attention to ensure that its use effect.

3. To help our our customer to solve actual problems and reach their goal quickly and valuablely.

4. Tracking and maintenance of the products,to ensure the production line is

quite stable and smooth,to create sustainable value for our customers.

5. Starting maintenance at the first time and improving the service efficiency,so that customers can enjoy more convenient and comprehensive service.

6.Regular visits to customers and maintainning good communication.we will take instructions from the clients about processing technology,products usage condition and the actual demand ,etc.