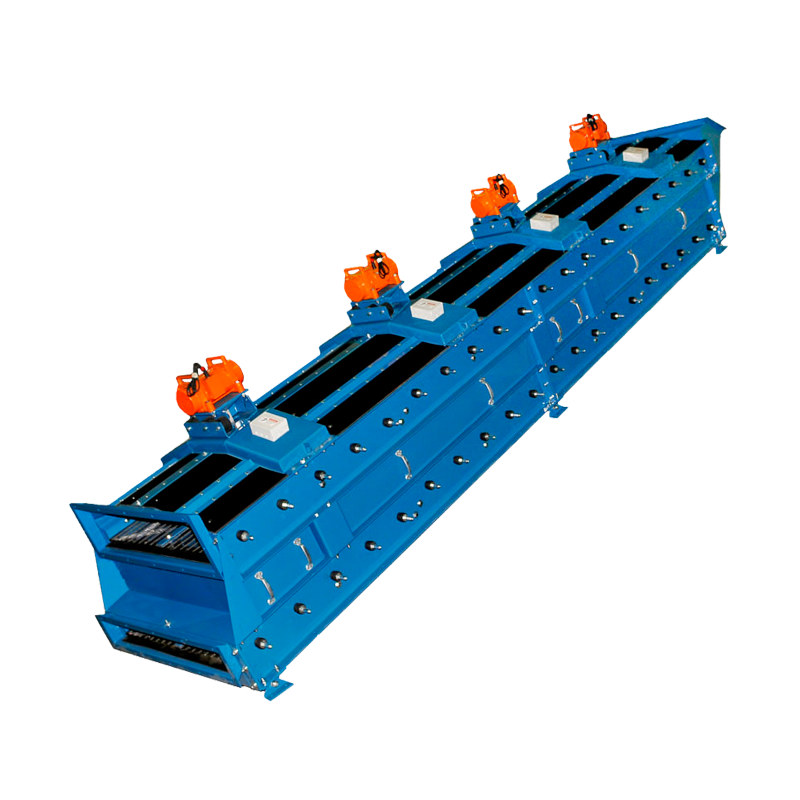

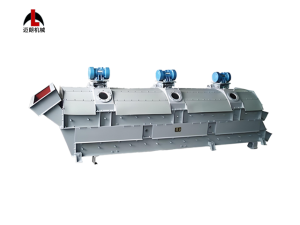

Mirant's Mesh Vibrating Screen is designed and manufactured by absorbing international modern advanced technology, suitable for the classification of loose compound fertilizers and fine materials. It is often used as a primary and secondary product screen.

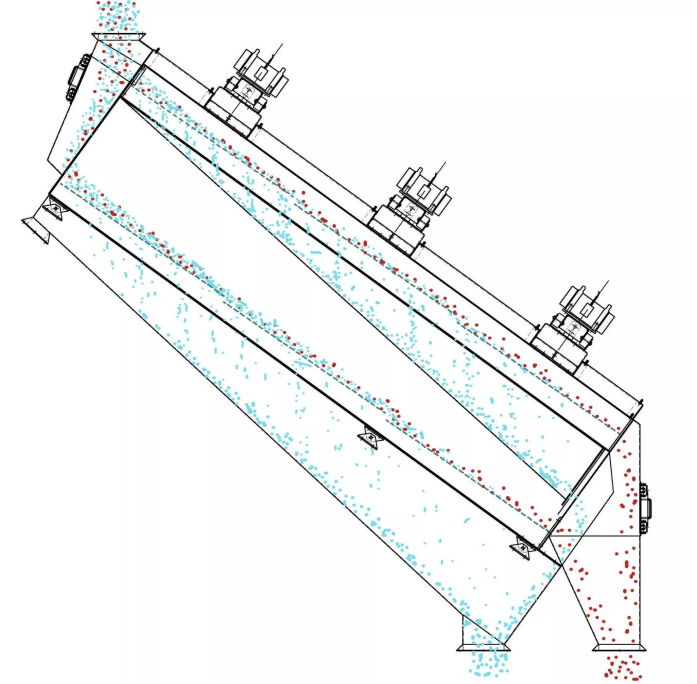

The upper part has a large mesh design to remove oversized particles from the product flow, where it can be moved to the crusher recovery process. The lower screen separates the product size from the fine particles. These fine particles are also sent back to the recycling station or used for seed products to the pelletizer. A separate discharge flange sends the product size material for further processing.

Mirant's Mesh Vibrating Screen is designed and manufactured by absorbing international modern advanced technology, suitable for the classification of loose compound fertilizers and fine materials. It is often used as a primary and secondary product screen.

The upper part has a large mesh design to remove oversized particles from the product flow, where it can be moved to the crusher recovery process. The lower screen separates the product size from the fine particles. These fine particles are also sent back to the recycling station or used for seed products to the pelletizer. A separate discharge flange sends the product size material for further processing.

1. Large processing capacity and high screening efficiency.

2. Good sealing, dustproof and easy maintenance.

3. Adjustable screen width for easy operation.

4. Good sealing, dustproof and easy maintenance.

5. Small dynamic load and low noise.

Mirant's Mesh Vibrating Screen uses "excellent vibration motor" as the power source to drive the mesh and frame to vibrate, thereby achieving material classification.

It consists of a feeder, a hopper, and a vibrating screen device. The material is evenly spread to the screen surface by the feeder, and then separated into upper and lower materials (taking a single screen as an example). It uses a vibration motor as the power source to drive the mesh and frame to vibrate to achieve material classification. Its amplitude can be adjusted to adapt to different material classifications. The vibration of the screen can prevent the screen from being blocked on the one hand, and on the other hand, it can make the material jump forward to achieve classification. This is why the Mesh Vibrating Screen has a large capacity and high screening efficiency.

Model | ZWS1230 | 2ZWS1230 | ZWS1245 | 2ZWS1245 | ZWS1260 | 2ZWS1260 | |

Sieve | layers | 1 | 2 | 1 | 2 | 1 | 2 |

Areas(㎡) | 3.6 | 3.6 | 5.4 | 5.4 | 7.2 | 7.2 | |

Screen Inclination (º) | 37 | 33 | 37 | 37 | 20 | 37 | |

Mesh Size (mm) | 10×40 | Upper:4×50 Lower:1.4×50 | Upper:4×50 Lower:1.4×50 | Upper:4×50 Lower:1.4×50 | 4×25 | Upper:4×50 Lower:1.4×50 | |

Structure | Woven mesh | Woven mesh | Woven mesh | Woven mesh | Woven mesh | ||

Granule Size (mm) | ≤60 | ≤60 | ≤60 | ≤60 | ≤60 | ||

Productivity (t/h) | 30-35 | 30-35 | 45-60 | 45-60 | 60-90 | ||

Frequency (1/min) | 1450 | 1450 | 1450 | 1450 | 1450 | ||

Double Amplitude (mm) | 3-5 | 3-5 | 3-5 | 3-5 | 3-5 | ||

Vibration Direction Angle | 90 | 90 | 90 | 90 | 90 | ||

Vibration Motor | Power (KW) | 0.75×2 | 0.75×2 | 0.75×3 | 0.75×3 | 0.75×4 | |

Exciting Force (KN) | 16×2 | 16×2 | 16×3 | 16×3 | 16×3 | ||

Weight (KG) | 1623 | 2300 | 2631 | 3612 | 3290 | ||

Overall Dimension(mm) | 3090×1700 ×3170 | 3300×1680 ×3300 | 4250×1660 ×5066 | 4496×1660 ×5648 | 6576×1660 ×4240 | 5678×1660 ×6156 | |

1. Are you factory?

Answer: Yes, established in 1985, over 35 years history.

2. How about the quality of your products?

Answer: Our products are manufactured strictly according to national and international standard, and we will take a test on every product before delivery.

3 . How about price?

Answer: For the complete same machine, we can promise our quality is the best when the price same as other competitors, and our price can be the most reasonable when the quality at standard level.