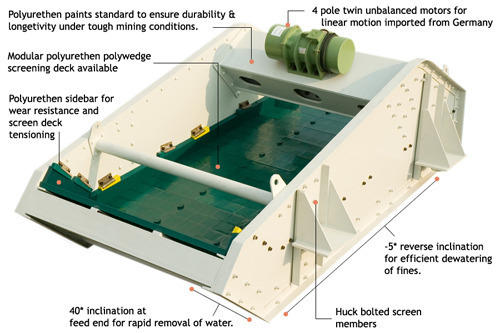

Mirant's Banana Vibrating Screen is an efficient ideal screening equipmen. The machine is made up of vibration device, screen box, dust cover, hopper, vibration damper device and a base, vibration device regards energy-saving vibration motor as exciting source, vibration damper device is suported and separated by the spring.

1. Small size, big screening capacity.

2. Light weight, easy to install and fix up.

3. Less energy consumption, can save energy.

4. Simple structure, attractive appearance, less spare parts.

5. Screen mesh is fitted by nubbles, easy to exchange.

6. Screen mesh is make up of wear-resisting bars and wears well.

7. Difficult to block feed because of grading feeding.

Mirant's Banana Vibrating Screen is widely used for the screening and grading operation of bulky, medium and a small granule materials in the industry, such as: mine, coal, electric power, fireproof material, metallurgy, building material and so on.

Model

| Screen area (㎡) | Inclination (o°) | Material size (mm) | Mesh Size (mm) | Capacity (t/h) |

Frequency (Hz)

| Double Amplitude (mm) | Motor | ||

Type | KW | V | ||||||||

ZSGB-1536 | 5.4 | 15 | <200 | 3 5 10 15 20 25 30 | 50-360 | 12 | 8-12 | JZ-75-6 | 2X4.0 | 380 |

ZSGB-1540 | 6 | 15 | 50-400 | JZ-75-6 | 2X4.0 | |||||

ZSGB-1836 | 6.48 | 15 | 60-460 | JZ-100-6 | 2X5.5 | |||||

ZSGB-1550 | 7.5 | 15 | 70-400 | JZ-100-6 | 2X5.5 | |||||

ZSGB-1848 | 8.64 | 15 | 80-500 | JZ-130-6 | 2X5.5 | |||||

ZSGB-2040 | 8 | 15 | 80-560 | JZ-130-6 | 2X5.5 | |||||

ZSGB-2050 | 10 | 15 | 90-600 | JZ-160-6 | 2X7.5 | |||||

2ZSGB-1536 | 5.4 | 15 | 50-360 | JZ-100-6 | 2X5.5 | |||||

2ZSGB-1540 | 6 | 15 | 50-400 | JZ-100-6 | 2X5.5 | |||||

2ZSGB-1836 | 6.48 | 10 | 60-460 | JZ-130-6 | 2X5.5 | |||||

2ZSGB-1550 | 7.5 | 15 | 70-400 | JZ130-6 | 2X5.5 | |||||

2ZSGB-1848 | 8.64 | 15 | 80-500 | JZ-180-6 | 2X7.5 | |||||

2ZSGB-2040 | 8 | 15 | 80-560 | JZ-180-6 | 2X7.5 | |||||

2ZSGB-2050 | 10 | 15 | 90-600 | JZ-200-6 | 2X11 | |||||

Q1: How to solve the problem of blocking mesh?

All of most vibrating screen adopts bouncing ball and PU ring below every deck to cleaning screen surface, except the ultrasonic vibrating screen adopts ultrasonic cleaning systerm.

Q2: How to seal the machine?

Between two decks, it's adopt silica gel ring to seal. Then the clamp would lock two decks tightly with the extended copper nut.

Q3: Could this machine be refitted and designed technology to suit our production line?

Yes. All of machines in our factory could be customized by client's specific requirement such as the height from outlet to ground, the inlet shape&outlet shape, and the gate design on first deck. and the gate design on first deck.

Q4: How can i get the spare parts for machine?

The matched spares, such as seal ring, bouncing ball, screen plate, clamp screws and nut could be ordered one set or more as customer's need.