Mirant's TD Series Bucket Elevator uses rubber conveyor belt as traction component to complete material loading in a scooping manner.

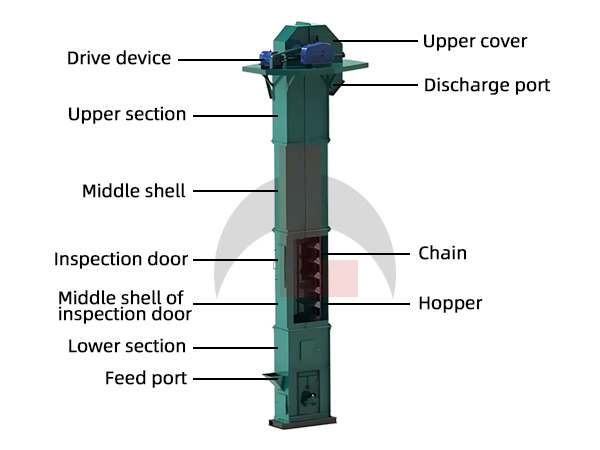

The loading feed port is located at the tail of the equipment, which is more conducive to material loading and transportation. When the material is put into the bottom of the elevator through the feed port, the bucket (i.e. hopper) is pulled by the conveyor belt and loaded with materials and moves upward at a uniform speed; when the bucket loaded with materials runs to the top, it is unloaded in a centrifugal or mixed manner; this completes the entire conveying process of the elevator.

Its transmission device has two types, equipped with YZ type reducer and ZQ (or YY) type reducer. YZ type shaft reducer is directly installed on the main shaft head, eliminating the transmission platform, coupling, etc., making the structure compact and light, and it has a special-shaped roller backstop inside, which is reliable. The reducer has low noise, stable operation, and floats with the main shaft, which can eliminate installation stress.

TD Series Bucket Elevator consists of running part (hopper and traction belt with upper section of transmission roller, lower section with tensioning roller, intermediate housing, drive device, check brake device, etc., suitable for upward conveying loose density ρ<1.5t/m3 powder, granular and small block non-abrasive and semi-abrasive bulk materials, such as coal, sand, coke, cement, crushed ore, etc.

Main Features:

1. Small driving power

Adopting inflow feeding, induction unloading, and large-capacity bucket intensive arrangement. There is almost no material return and digging phenomenon when the material is lifted, so the invalid power is small.

2. Wide lifting range

It has few requirements on the type and characteristics of materials, not only can it lift general powder and small granular materials, but also can lift materials with greater abrasiveness. Good sealing and less environmental pollution.

3. Good operating reliability

The design principle and processing method ensure the reliability of the whole machine operation, and the trouble-free time exceeds 20,000 hours. The lifting height is high. The elevator runs smoothly, so it can reach a higher lifting height.

4. Long service life

The feeding of the elevator adopts the inflow type, and there is no need to use a bucket to dig materials, and there is rarely squeezing and collision between materials. When designing this machine, it is ensured that the material is rarely scattered during feeding and unloading, reducing mechanical wear.

Mirant's TD Series Bucket Elevator is suitable for conveying loose density ρ<1.5t/m3 powder, granular and small block non-abrasive and semi-abrasive bulk materials, such as grain, coal, sand, coke, cement, crushed ore, etc. It is widely used in metallurgy, chemical industry, building materials, mining, grain and oil, food, feed, plastics, medicine and other industries.

| Model | Feed size | Conveying capacity | Bucket | Belt Width | |||

| Bucket width | Bucket distance | Bucket capacity | Bucket speed | ||||

| (mm) | (m³/h) | (mm) | (mm) | (L) | (m/s) | (mm) | |

| TD160 | 25 | 5.4-16 | 160 | 280,350 | 0.5-1.9 | 1.4 | 200 |

| TD250 | 35 | 12-35 | 250 | 360,450 | 1.3-4.6 | 1.6 | 300 |

| TD315 | 45 | 17-40 | 315 | 400,500 | 2-5.8 | 1.6 | 400 |

| TD400 | 55 | 24-66 | 400 | 480,560 | 3.1-9.4 | 1.8 | 500 |

| TD500 | 60 | 38-92 | 500 | 500,625 | 4.8-15 | 1.8 | 600 |

| TD630 | 70 | 85-142 | 630 | 710 | 14-23.5 | 2 | 700 |

| Note: The bucket capacity in the table is the calculated bucket capacity, and the conveying volume is calculated based on the filling factor of 0.6. | |||||||