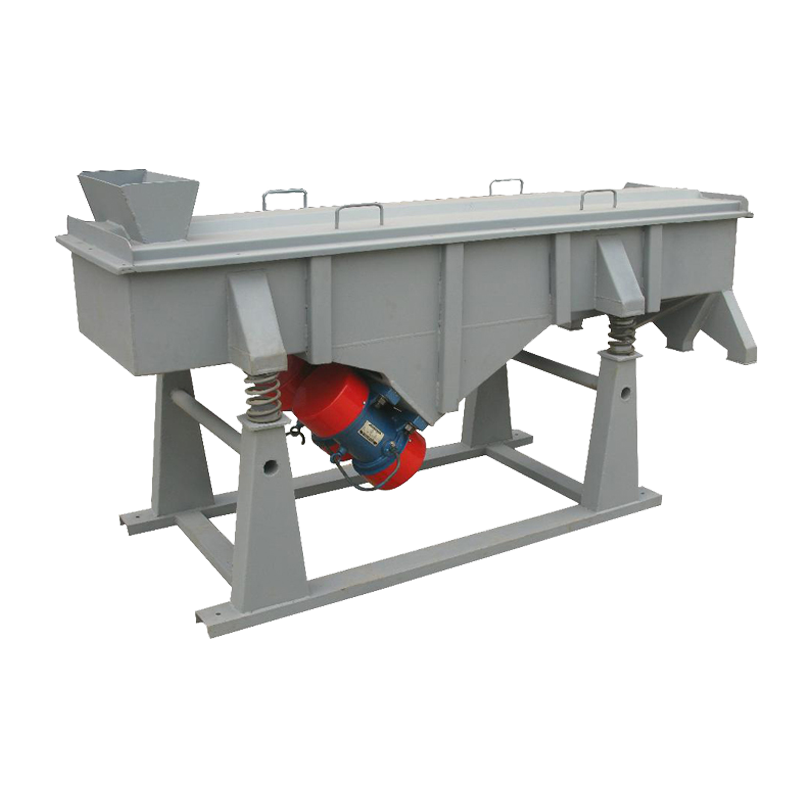

Mirant's Linear Vibrating Screen uses an excellent vibration motor as the power to throw the material upward on the screen surface and move forward in a straight line. The materials enter in the port evenly, and through multi-layer screening, materials of different sizes are screened out and dehydrated.

If equipped with single screen or multiple screens, it can finish grading, impurity removal, dust removal, inspection, washing, material selection and dehydration.

Mirant's Linear Vibrating Screen, driven by vibration motor, generates an exciting force through an exciter to move the screen box forward in a straight line. The material to be screened and graded is put into the screen box through feed port. Through vibration motor, the material in the screen box is affected by centrifugal force and inertial force and moves linearly on the screen. Smaller particles will pass through the pores of the screen, while larger particles will be blocked on the surface of the screen. During the screening process, materials that meet the requirements will pass through the screen and fall into the aggregate box or conveyor belt below, while materials that do not meet the requirements will be retained on the screen. The screening speed and screening effect of the material can be controlled by adjusting the amplitude and vibration frequency of the vibration motor to meet the screening requirements of different materials.

1. Stepped grid structure, no material mixing or leakage.

2. Long screen life, easy replacement and built-in screen cleaning structure.

3. Fully enclosed structure, energy saving and environmental protection.

4. High cost performance, easy maintenance, single or multi-layer is choicable.

Mirant's Linear vibrating Screen is mainly used for screening any dry materials without stickiness. It is mainly used for screening dry powder, fine granular or fine powder materials in industries such as abrasives and abrasive tools, chemicals, plastics, medicines, resin powders, ceramic raw materials, metallurgy, refractory materials, sandstone, building materials, food, fertilizers, etc.

MODEL | Screen area (mm) | No. of screen layers | Mesh (mm) | Frequency (r/min) | Double amplitude (mm) | Power (kw) | Screen angle (º) | Dimension(mm) |

ZXSF520 |

500×2000

| 1 | 2-200 | 960 | 6-7 | 2×0.4 | 45-60 | 2140×808×848 |

2ZXS520 | 2 | 960 | 6-7 | 2×0.4 | 45-60 | 2199×808×878 | ||

3ZXS520 | 500×2500

| 3 | 1450 | 4-6 | 2×0.4 | 45 | 2256×808×938 | |

ZCSF525 | 1 | 960 | 5-7 | 2×0.4 | 45-60 | 2642×808×848 | ||

2DZSF525 | 2 | 1450 | 4-6 | 2×0.4 | 45 | 2699×808×878 | ||

3ZXS525 | 3 | 960 | 6-8 | 2×0.75 | 45-60 | 2750×808×938 | ||

4ZXS525 | 4 | 1450 | 5-7 | 2×0.4 | 45 | 2813×808×1000 | ||

5ZXS525 | 5 | 1450 | 5-7 | 2×0.4 | 45 | 2883×808×1060 | ||

6ZXS525 | 6 | 960 | 6-8 | 2×0.75 | 45-60 | 2953×808×1120 | ||

ZXS1020 | 1000×2000 | 1 | 960 | 6-8 | 2×0.75 | 45-60 | 2152×1320×900 | |

2ZXS1020 | 2 | 960 | 5-7 | 2×0.75 | 45-60 | 2219×1320×960 | ||

3ZXS1020 | 1000×2000 | 3 | 2-200

| 960 | 5-7 | 2×0.75 | 45-60 | 2286×1320×1030 |

4ZXS1020 | 4 | 960 | 4-8 | 2×0.75 | 45-60 | 2353×1320×1100 | ||

5ZXS1020 | 5 | 960 | 4-8 | 2×1.5 | 45-60 | 2420×1320×1160 | ||

6ZXS1020 | 6 | 960 | 4-8 | 2×1.5 | 45-60 | 2487×1320×1220 | ||

ZXS1025 | 1000×2500

| 1 | 1450 | 5-7 | 2×0.4 | 45 | 2203×1320×900 | |

2ZXS1025 | 2 | 1450 | 5-7 | 2×0.4 | 45 | 2269×1320×960 | ||

3ZXS1025 | 3 | 960 | 6-8 | 2×0.75 | 45-60 | 2336×1320×1030 | ||

ZXS830 | 800×3000 | 1 | 960 | 6-8 | 2×0.75 | 45-60 | 3080×1098×1120 | |

2ZXS830 | 2 | 960 | 6-8 | 2×0.75 | 45-60 | 3140×1098×1180 | ||

3ZXS830 | 3 | 960 | 6-8 | 2×1.5 | 45-60 | 3200×1098×1240 | ||

ZXS1030 | 1000×3000 | 1 | 960 | 6-8 | 2×0.75 | 45-60 | 3152×1340×1120 | |

2ZXS1030 | 2 | 960 | 6-8 | 2×1.5 | 45-60 | 3219×1340×1120 | ||

3ZXS1030 | 3 | 960 | 6-8 | 2×1.5 | 45-60 | 3286×1340×1120 | ||

ZXS1224 | 1200×2400 | 1 | 960 | 6-8 | 2×0.75 | 45-60 | 2480×1520×1100 | |

2ZXS1224 | 2 | 960 | 6-8 | 2×0.75 | 45-60 | 2540×1520×1160 | ||

3ZXS1224 | 3 | 960 | 6-8 | 2×1.5 | 45-60 | 2600×1520×1220 |

Meet different needs of customers.

1. We offer accurate quotation according to your model or drawings.

2. We can help you design the whole line based on your model.

3. OEM and label service will be always available.

1. 24 hours service online.

2. Quality warranty.

3. Provide assembly instruction, technical date and related soft copies or video to ensure customer could install and debug by themselves.