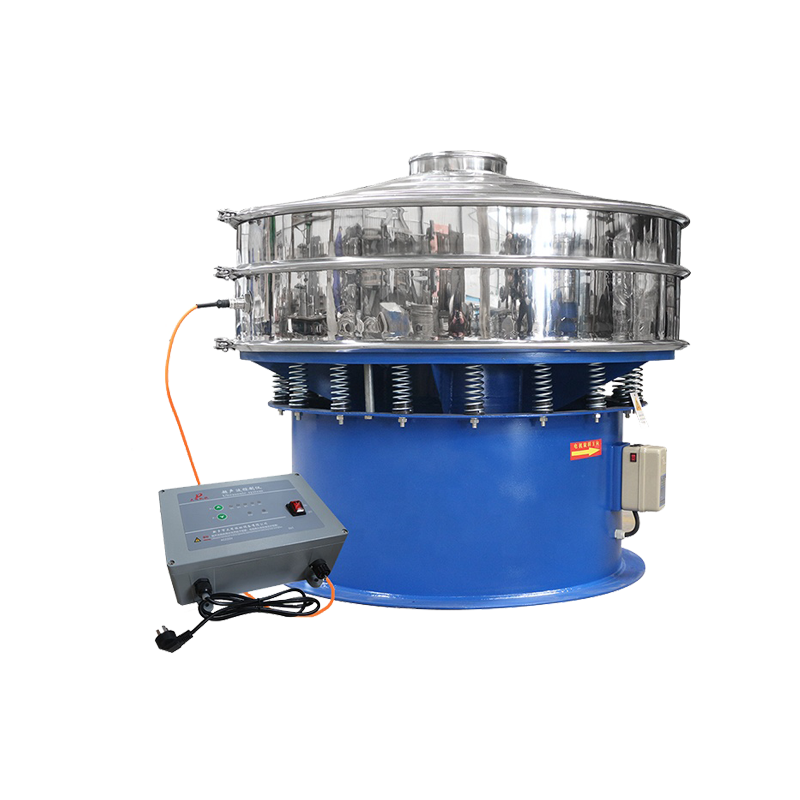

Mirant's Ultrasonic Vibrating Screen is a high-precision screening equipment. It consists of an ultrasonic generator, a transducer, and a resonant ring, which is an important breakthrough in screening efficiency.

It adopts an advanced intelligent vibration ultrasonic controller, which solves many problems caused by single frequency and truly realizes the reasonable combination of ultrasonic function and vibrating screen.

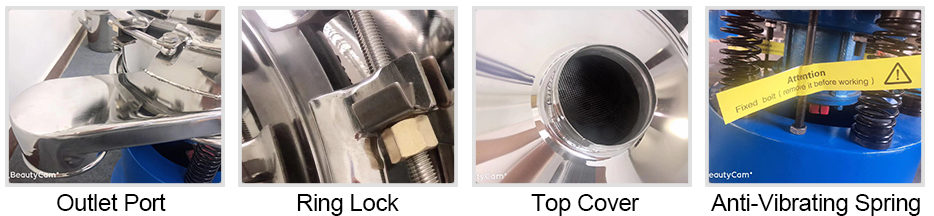

The working principle of Mirant's Ultrasonic Vibrating Screen is to add ultrasonic energy conversion device on the screen surface of three-dimensional vibration separator and filter. This device can superimpose ultra-high frequency vibration energy on the screen surface, so that it can keep the grid clear and achieve ideal screening conditions. Ultrasonic vibrating screen is usually used to screen ultra-fine powders that ordinary vibrating screen cannot solve.

1. It can solve the problems of high adsorption, easy aggregation, high static, high precision, high density and light specific gravity in screening.

2. Effectively control the screening particle size scale to achieve high-precision screening

3. The screening accuracy can be increased to 1-70%, and the production capacity can be increased by 0.5-10 times.

4. It can be used in single layer or 1-5 layers.

5. As a set of intelligent ultrasonic generators, it can be used with three controllers at the same time.

6. Self-cleaning function: 10-600 minutes screening without blocking the sieve hole and with stable screening efficiency.

7. No change with the processing material characteristics.

8. The whole machine is made of 304 stainless steel or 316L stainless steel,which could be used in medicine, food, chemical industry, etc.

Mirant's Ultrasonic Vibrating Screen solves the screening problems of strong adsorption, easy agglomeration, high static electricity, high fineness, high density, light specific gravity, etc., making ultrafine powder screening no longer a difficult task, especially suitable for users of high-quality and fine powder.

Applicable materials: Chinese and Western raw materials, Western medicine, coffee powder, cocoa powder, condiments, food additives, metal powder, copper, iron, aluminum, lead, zinc, alloy powder, magnetic materials, metal powder, alumina, corundum, corundum, quartz sand glass powder beads, grinding materials, plastics, rubber, resin, dyes, fillers, chemical chemistry, activated carbon, wood powder, sawdust, charcoal, fiber materials and other materials.

Model | UXZS-600 | UXZS-800 | UXZS-1000 | UXZS-1200 | |

Sieve diameter(mm) | Φ560 | Φ760 | Φ950 | Φ1150 | |

Effective sieving area(m²) | 0.2289 | 0.4183 | 0.6359 | 0.9499 | |

Mesh(mm) | 2~600 | ||||

Layer(s) | 1-5 | 1-5 | 1-5 | 1-5 | |

Motor power (kw) | Vibration motor | 0.25 | 0.55 | 0.75 | 1.1 |

| General motor | 0.75 | 1.1 | 1.5 | 1.5 | |

Note:

We can design and manufacture unstandard models and specifications of screening machines according to your need. And we reserves the right to modify all technical data and dimensions. If the actual product doesn't match the data, the actual product shall prevail.

1. Product packing meets customers' demands.

2. Shipping according customer's demands.

1. Help high-end customer to choose suitable machine and develop local market.

2. Accurate quotation according to customer's model or drawings.

3. The drawing can be send if needed, we can help you design the whole line based on your model.

4. OEM and label service.

1. 24 hours service online.

2. Quality warranty.

3. Provide assembly instruction, technical date and related soft copies or video to ensure customer could install and debug by themselves.

Q1: Why choose our machine?

A: Our company are specializing in all kinds of vibration screen more than 15 years. We have professional team to research and develop new and unique vibration.

Q2: What's raw material name? Bulk density (kg/m³)and water content (%)?

EM: Grain, Liquid, sand.......

Q3: How much mesh size do you want (mesh size of each layer)?

Single layer or Multi-lyayer is available. it's also can be customized by your requirements.

Q4: What's usually local power supply ______Voltage& ______Frequency in your city ?

Various power voltage: 110V 200V 240V 380V 415V 450V 550V

Power Frequency: 50HZ 60HZ or Single phase electricity

Q5: What's material for machine do you need?

A Stainless steel 304

B Carbon steel Q235

C Touching parts SUS304

Q6: How do you ensure the quality of your products?

A: Generally, our equipments are the most durable type in the industry, this is also the feature of the label impression of the most of our customers at home or abroad.

Q7: How do your after-sale service work if the product got damaged?

A: During the maintenance period, our general after-sale service is changing the damaged parts for the customer. Normally, we will provide on-site guidance.