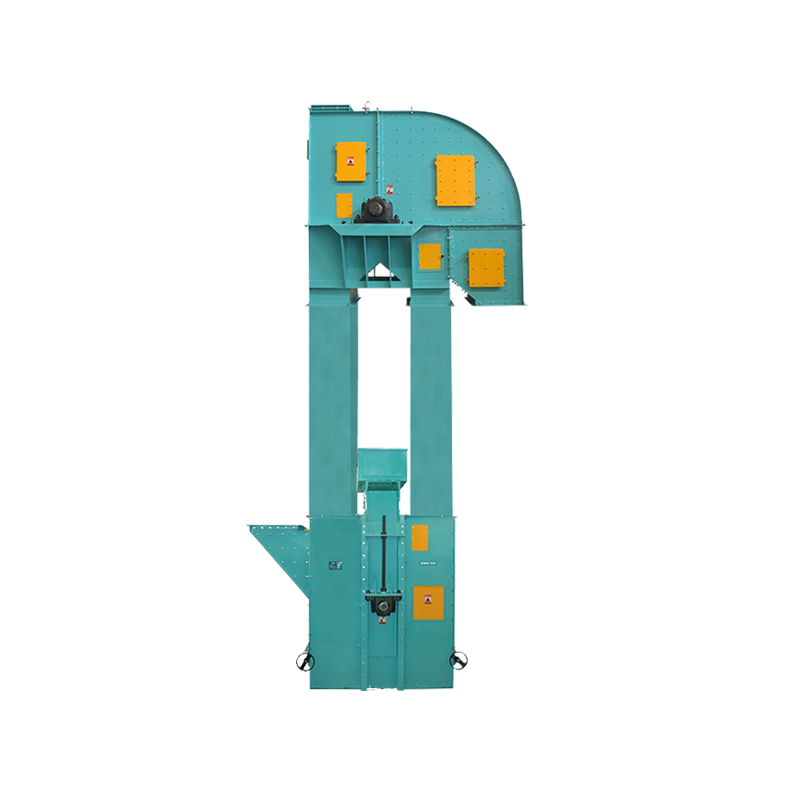

Mirant's TH/HL chain bucket elevator uses a chain as a traction mechanism to transport materials. It is suitable for vertical transportation of abrasive powder, granular, and small block materials, such as grain, coal, cement, crushed ore, etc. The maximum conveying height is 40m.

TH type chain bucket elevator uses chain as traction component to complete material loading by scooping. The loading feed port is located at the tail of the equipment, which is more conducive to the loading and conveying of materials. When the material is put into the bottom of the elevator through the feed port, the bucket (i.e. the hopper) is pulled by the chain and loaded with materials and runs upward at a uniform speed; when the bucket loaded with materials runs to the top, it is unloaded by centrifugal or mixed method; thus completing the entire conveying process of the elevator.

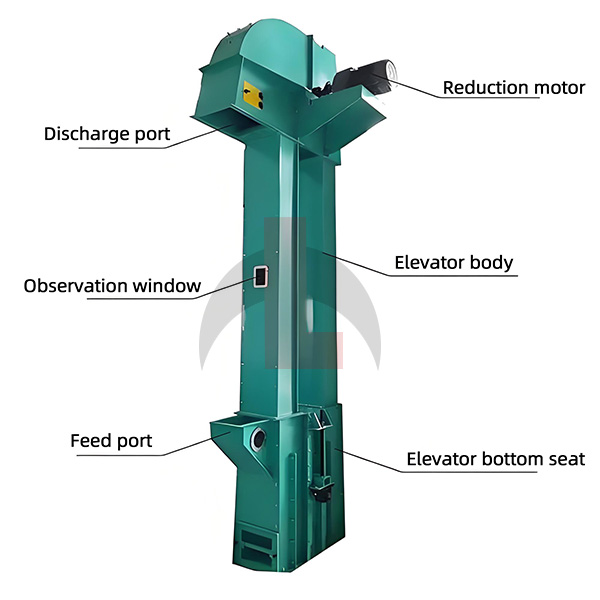

TH elevator equipment consists of a moving part (hopper and traction chain), an upper section with a transmission sprocket, a lower section with a tension wheel, an intermediate housing, a drive device, a backstop brake device, etc.

TH type chain bucket elevator is suitable for conveying powder, granular and small block non-abrasive and semi-abrasive bulk materials, such as grain, coal, sand, coke, cement, crushed ore, etc. It is widely used in metallurgy, chemical industry, building materials, mining, grain and oil, food, feed, plastic, medicine and other industries.

Model | TH160 | TH200 | TH250 | TH315 | TH400 | TH500 | TH630 | TH800 | TH1000 | |||||||||

Hoper Type | Zn | Sh | Zn | Sh | Zn | Sh | Zn | Sh | Zn | Sh | Zn | Sh | Zn | Sh | Zn | Sh | Zn | Sh |

Capacity (m³/h) | 8 | 12 | 13 | 22 | 16 | 28 | 21 | 36 | 36 | 56 | 45 | 70 | 68 | 110 | 87 | 141 | 141 | 220 |

Hopper Width(mm) | 160 | 200 | 250 | 315 | 400 | 500 | 630 | 800 | 1000 | |||||||||

Hopper Volume (L) | 1.2 | 1.9 | 2.1 | 3.2 | 3.0 | 4.6 | 3.75 | 6 | 5.9 | 9.5 | 9.3 | 15 | 14.6 | 23.6 | 23.3 | 37.5 | 37.6 | 58 |

Hopper Distance (mm) | 320 | 400 | 500 | 500 | 600 | 688 | 688 | 920 | 920 | |||||||||

Chain | Φ8x30 | Φ12x40 | Φ18x50 | Φ18x50 | Φ18x50 | Φ22x86 | Φ22x86 | Φ26x92 | Φ26x92 | |||||||||

Sprocket Pitch (mm) | 400 | 500 | 600 | 630 | 710 | 800 | 900 | 1000 | 1250 | |||||||||

Speed (m/s) | 1.25 | 1.25 | 1.4 | 1.4 | 1.4 | 1.5 | 1.5 | 1.6 | 1.6 | |||||||||

Max Granularity(mm) | 18 | 25 | 32 | 45 | 55 | 65 | 75 | 85 | 100 | |||||||||