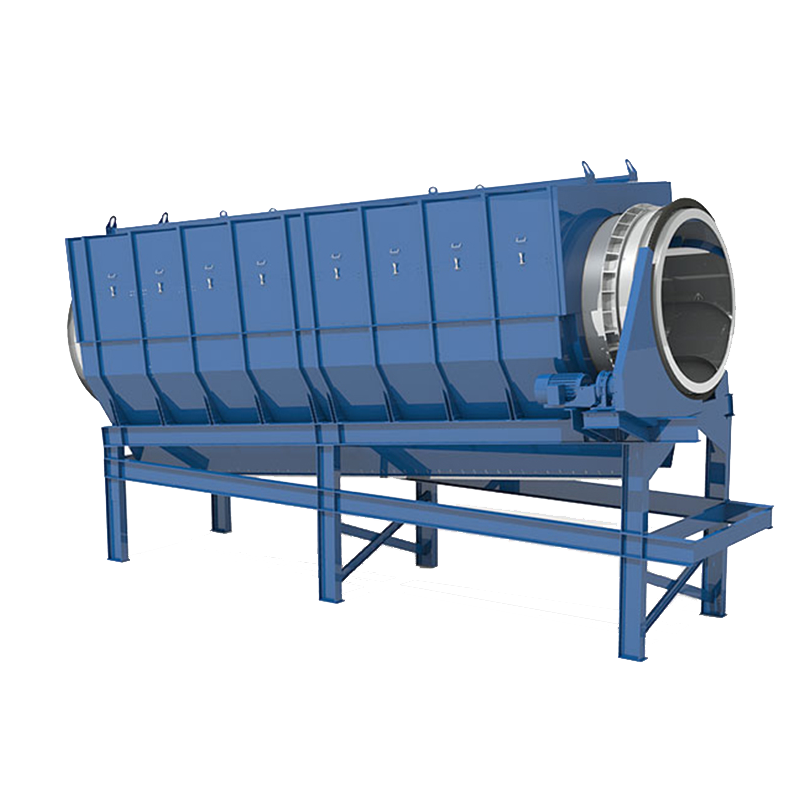

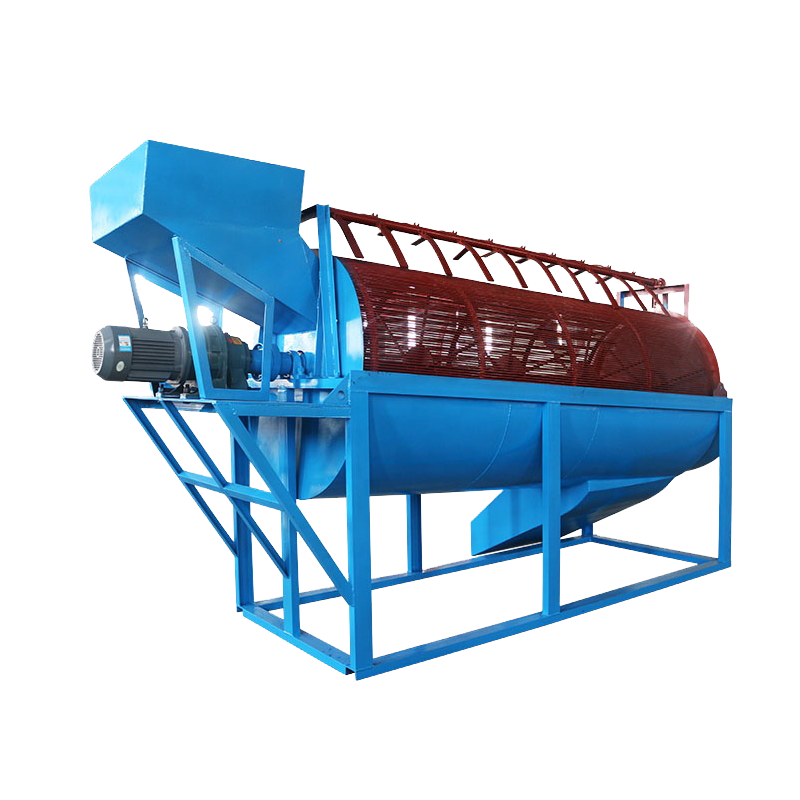

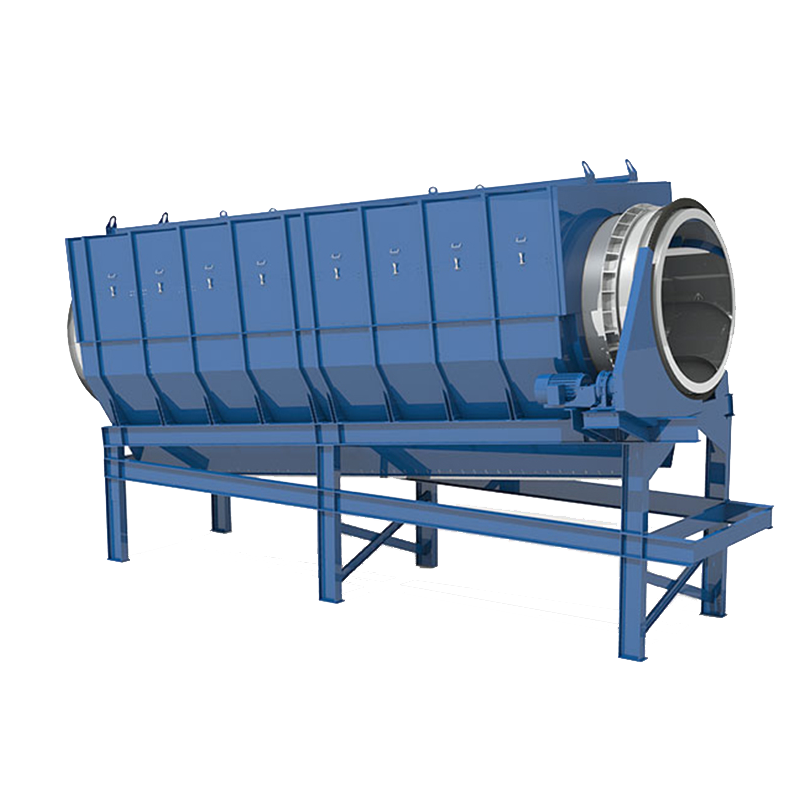

Mirant's Trommel Screen is a special screening equipment developed for power plant, coking plant, building materials, metallurgy, chemical, mining and other industries. it overcomes the problem of screen clogging caused by circular vibrating screen and linear screen in sieving wet materials, and improve the output and reliability of screening system.

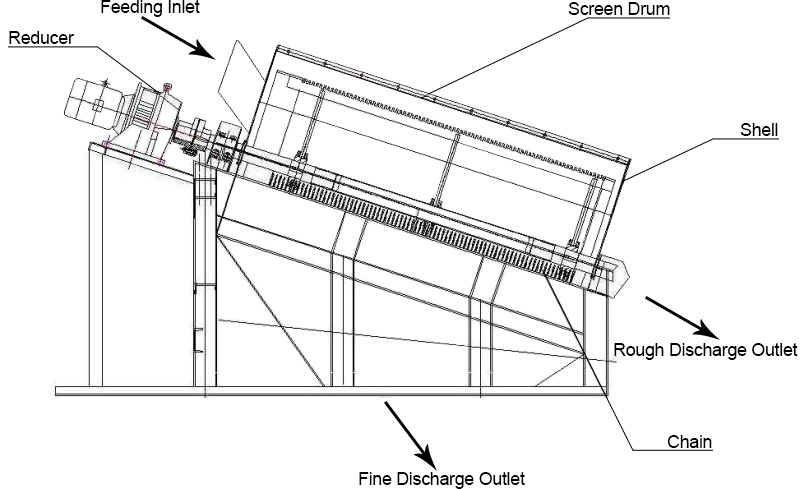

It is composed of 5 parts: the hexagonal roller, frame, funnel, reducer and motor, which can be designed by the actual production needs.

1. Adopting the rolling conveying principle, the friction coefficient is small, the wear is light, and the screen hole is not easy to be blocked.

2. The drum support adopts an integral through-shaft structure, which runs smoothly, does not vibrate, and has low noise.

3. The internal drum screen accessories adopt a split design, with a simple structure, quick and convenient replacement and maintenance.

4. The drum body can adopt an effective full-sealed structure, which does not raise dust or pollute.

5. The operation is safe and reliable, and the reduction transmission is adopted, with high transmission efficiency, low power, low energy consumption, and obvious energy-saving effect.

6. Different screen materials and screen hole sizes can be used according to customer requirements, with high screening efficiency, long service life, and low maintenance cost.

During operation, the Trommel Screen moves slowly and steadily, is easy to install, and sometimes does not require a special foundation. It can be placed on a smooth ground or floor. It is suitable for screening materials of various properties, as well as wet and easily blocked materials such as coal, coal gangue, coke, and slaked lime. The maximum size of the screened product is 100mm, the middle is 10-50mm, and the finest can reach less than 3mm. It is widely used in screening and grading in power plants, coking plants, building materials, metallurgy, chemical industry, mining and other industries.

Model | Capacity (t/h) | Capacity (Kw) | Screen Diameter (mm) | Screen length (mm) | Discharge Size(mm) | Input size (mm) | Dimension(mm) | Weight (kg) |

GZ1025 | 50 | 3.0 | 1000 | 1500 | 1-100 | ≤300 | 2600*1400*1700 | 2200 |

GZ1020 | 100 | 4.0 | 1000 | 2000 | 1-100 | ≤300 | 3390*1400*2140 | 2800 |

GZ1225 | 160 | 5.5 | 1200 | 2500 | 1-100 | ≤300 | 4146*1600*2680 | 4200 |

GZ1530 | 250 | 7.5 | 1500 | 3000 | 1-100 | ≤300 | 4460*1900*2820 | 5100 |

GZ1545 | 350 | 11 | 1500 | 4500 | 1-100 | ≤400 | 4960*1900*3080 | 6000 |

GZ1848 | 450 | 15 | 1800 | 4800 | 1-100 | ≤400 | 6500*2350*4000 | 7500 |

GZ2055 | 600 | 22 | 2000 | 5500 | 1-100 | ≤400 | 7500*2250*4800 | 9600 |

GZ2265 | 800 | 30 | 2200 | 6500 | 1-100 | ≤400 | 8500*2750*5000 | 128000 |

1. Help high-end customer to choose a suitable machine and develop local market.

2. We can offer an accurate quotation according to customer's model or drawings.

3. The drawing can be send if needed, we can help you design the whole line based on your model.

4. OEM and label service will be always available.

1. 24 hours service online and fast response within 12 hours.

2. Quality warranty is 12 months from the shipping date.

3. Provide assembly instruction, technical date and related soft copies or video to ensure customer could install and debug by themselves.