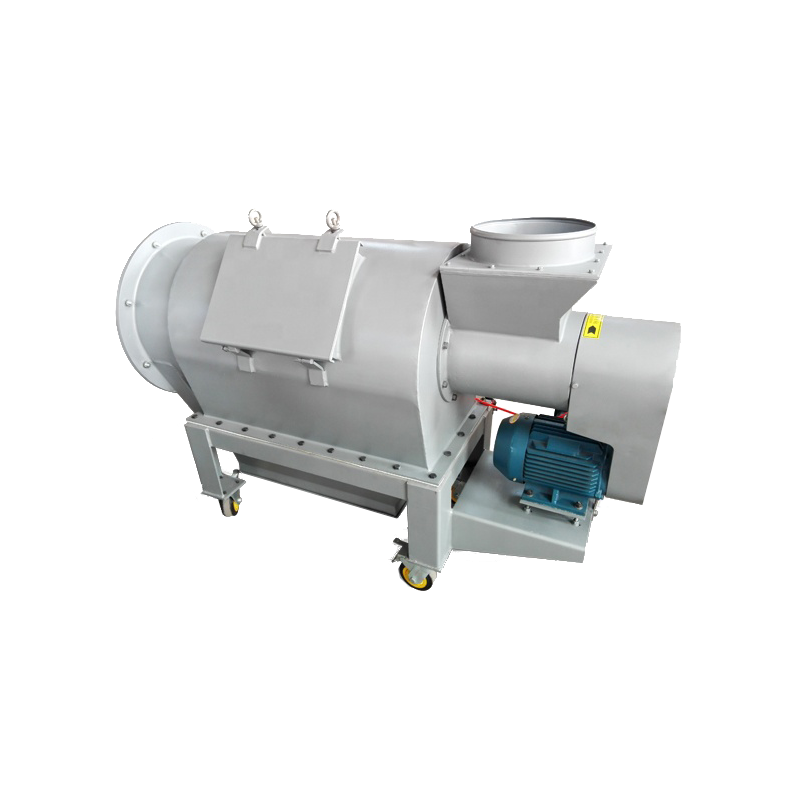

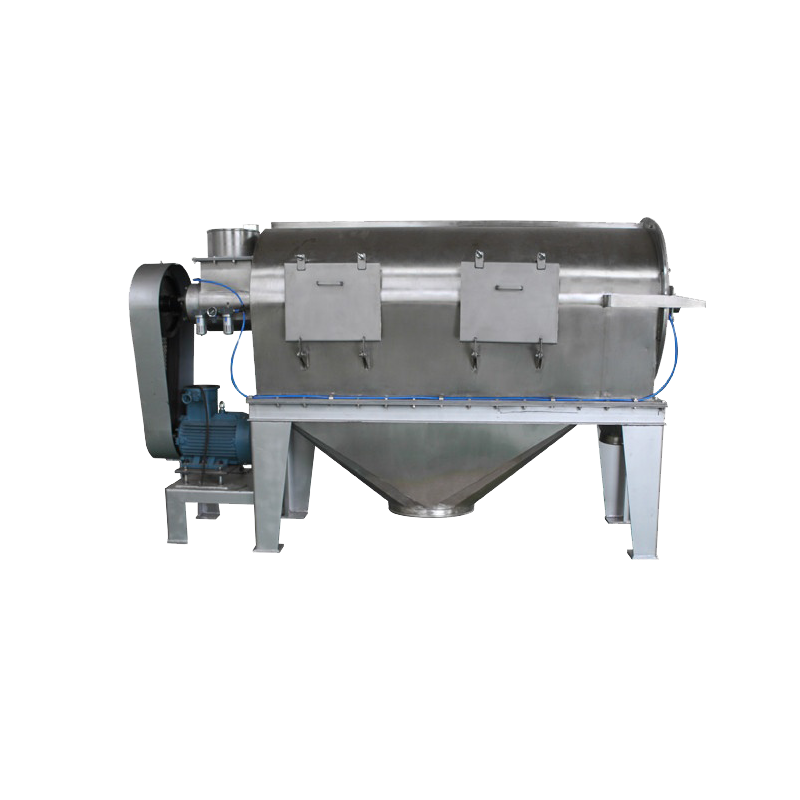

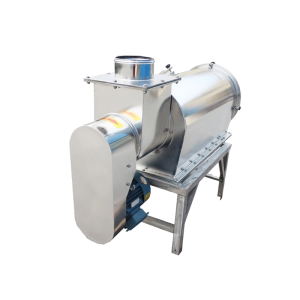

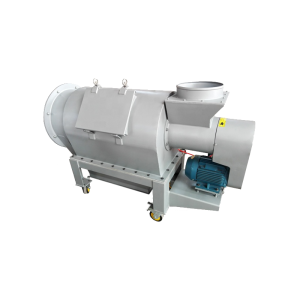

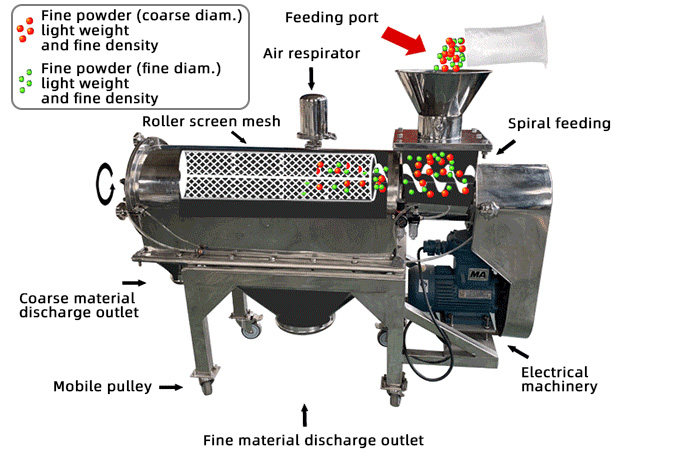

The cylinder sieve is also called horizontal airflow screen or horizontal airflow sieving machine due to the shape of sieve cylinder, placed inside the machine. The material enter the net tube with airflow mixed and atomized after pass through the screw conveying system; some of the material are sprayed through the screen cloth and discharged from the fine stuff outlet by the centrifugal force and cyclone propelling power, which are caused by the rotor vanez inside the net tube. Other materials which cannot cross the net, are discharged from the rough stuff portal along the net tube wall.

1. The whole machine is a small size and light so that it is stable in operation.

2. Good seal performance, Convenient installment.

3. The machine can operate either in a single unit or multiple units, which is reliable for a long time operation.

4. The screen cloth can be cleanned automatically by cyclone.

5. The machine has the function of re-crashing the agglomeration materials.

6. The new type roller bearing is very durable.

7. The machine can work with the pneumatic conveying system, and material can be directly sent into the wind path to save resource.

Model | Power(w) | Sieving Diameter(mm) | Max Excting Force(kg) | Weight(kg) |

MLQW-450 | 250 | 420 | 180 | 50 |

MLQW-600 | 370 | 550 | 350 | 65 |

MLQW-800 | 550 | 760 | 680 | 78 |

MLQW-1000 | 750 | 930 | 1000 | 130 |

MLQW-1200 | 1100 | 1130 | 1300 | 170 |

1. Providing technical advisory services to customers.

2. We can offer an accurate quotation according to customer's model or drawings.

3. The drawing can be send if needed, we can help you design the whole line based on your model.

4. OEM and label service will be always available.

1. 24 hours service online and fast response within 12 hours.

2. Quality warranty is 12 months from the shipping date.

3. Regular tracking and accessories supply, and handling customer feedback efficiently.

4. Provide assembly instruction, technical date and related soft copies or video to ensure customer could install and debug by themselves.