Mirant's Vertical vibration Elevator is applicable to materials of powder, block and short fibre, and widely used in chemical industry, rubber, plastic, medicine, light industry, metallurgy, building material, machinery, mine, food and other Industries.

The material not only can be lifted, but also can be dried and cooled at the same time.

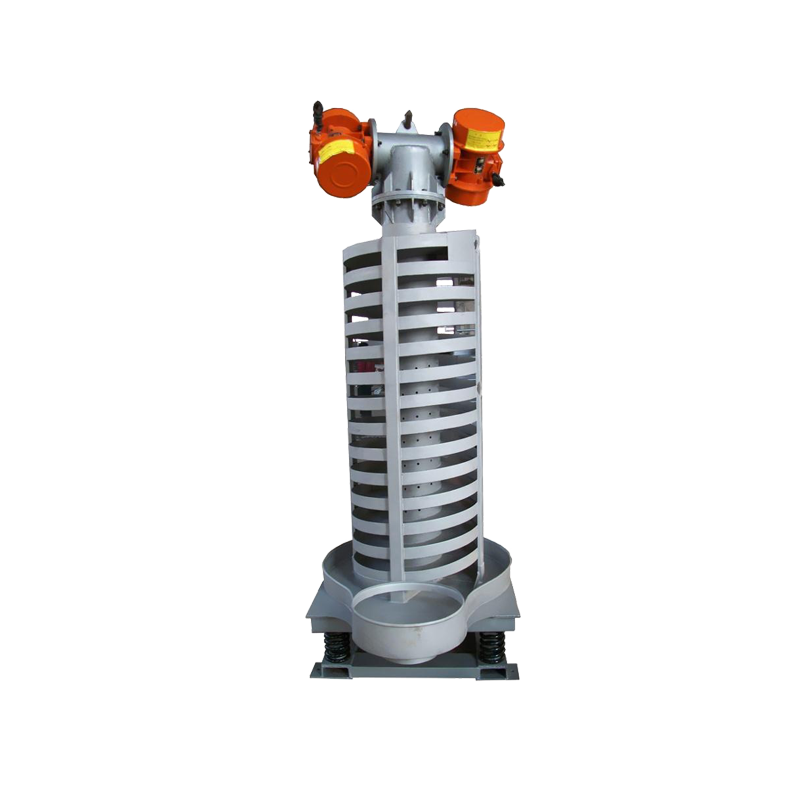

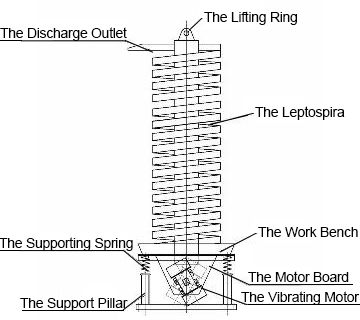

The driving vibration motor of Vertical Vibration Elevator is installed at the bottom or top of the conveying tower. The two vibration motors are installed symmetrically and crosswise. When the vertical elevator is working, according to the self-synchronization principle of the double vibration motors, the vibration motor generates an exciting force, forcing the entire conveying tower body to perform a spatial composite vibration of horizontal circular motion and upward vertical motion. The material is affected by the conveying trough and performs a uniform throwing circular motion, moving upward along the conveying trough body, thereby completing the upward conveying operation of the material. While lifting the material upward, the Vertical Vibration Elevator can also complete the drying and cooling of the material.

Its structure is divided into two types: trough type and closed type, which can be divided into water-cooled and air-cooled elevators according to different process requirements.

1. Reasonable and simple structure, easy maintenance, adjustable outlet.

2. Low power consumption, low noise.

3. Dust-proof, heat-proof, oil-proof and explosion-proof.

4. Two types available to choose: open type and sealed type.

5. Small spce occupation, totally sealed structure can effectively avoid dust and harmful gas pollution.

6. Material can be cooled or dried during the lifting process according to customer's special request.

---Drying

Using the heat air to blow away the moisture after washing.

---Cooling

The elevator can be connect to source of cooling air to low down the temperature of material to ambient temperature, apply to the process of heating and roasting.

Mirant's Vertical Vibration Elevator is widely used in material lifting in mining, metallurgy, machinery, building materials, chemical industry, rubber, medicine, electricity, grain, food and other industries.

Model | Diameter of spiral chute(mm) | Lifting height(m) | Speed(r/min) | Double amplitude(mm) | Power(w) |

MLC300 | 300 | <=7.0 | 960 | 6-8 | 2*0.4 |

MLC500 | 500 | <=7.0 | 2*0.75 | ||

MLC600 | 600 | <=7.0 | 2*1.5 | ||

MLC800 | 800 | <=7.0 | 2*2.2 | ||

ML900 | 900 | <=7.0 | 2*3.0 | ||

MLC1200 | 1200 | <=7.0 | 2*4.5 | ||

MLC1500 | 1500 | <=7.0 | 2*5.5 | ||

MLC1800 | 1800 | <=7.0 | 2*6.5 |

1. Help high-end customer to choose a suitable machine and develop local market.

2. We can offer an accurate quotation according to customer's model or drawings.

3. The drawing can be send if needed, we can help you design the whole line based on your model.

4. OEM and label service will be always available.

1. 24 hours service online and fast response within 12 hours.

2. Quality warranty is 12 months from the shipping date.

3. Provide assembly instruction, technical date and related soft copies or video to ensure customer could install and debug by themselves.