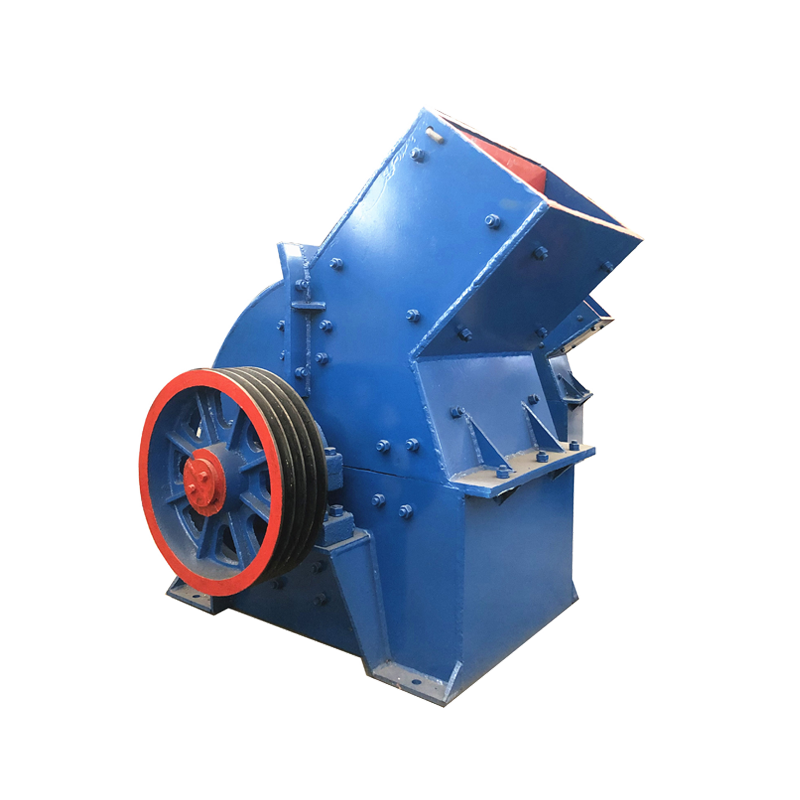

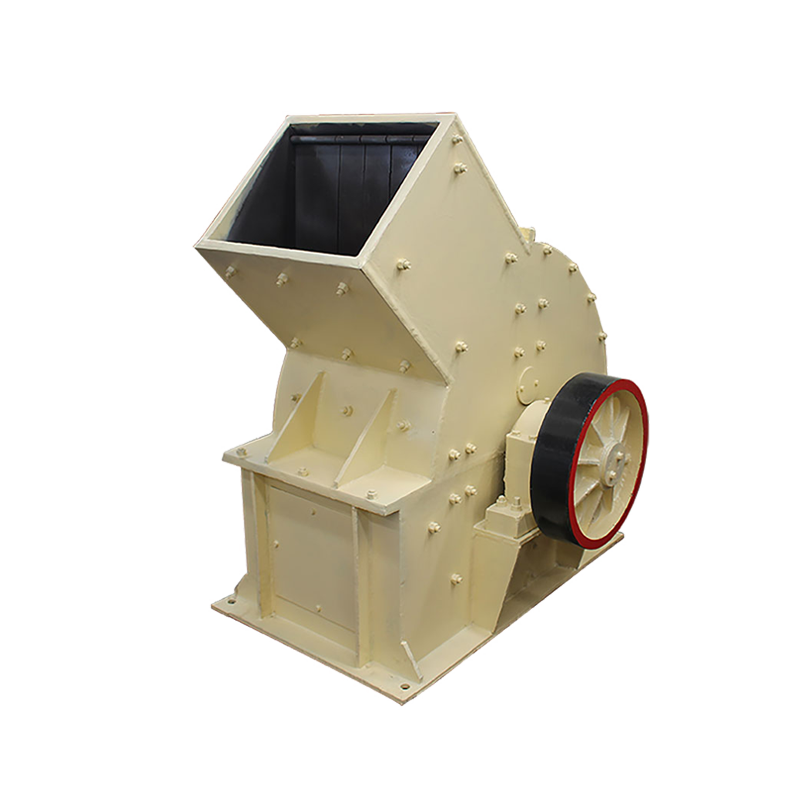

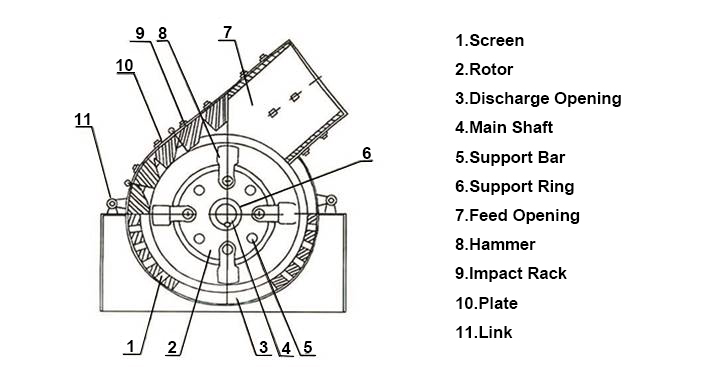

Mirant's Hammer Crusher is a ring-shaped machine with an impact rotor. When the material enters the crushing chamber from the upper feed port, the motor drives the rotor to rotate rapidly in the crushing chamber. Then it is impacted, sheared and ground by the high-speed moving hammer.

The screen plate is installed at the bottom of the rotor, so that the crushed particles smaller than the size of the screen can be discharged through the screen plate, while the crushed stones larger than the opening size of the screen will remain on the screen plate and be ground and impacted into qualified particles, and finally discharged by the screen plate.

1. It adopts heavy hammer crushing, without secondary crushing process, which can reduce costs by about 40% and consume less energy.

2. Compared with the jaw crusher of the same scale of output, it can reduce equipment investment by 45%.

3. Compared with the caster crusher, in the working environment with moist materials and more soil, it eliminates blockage and adhesion, reduces the consumption of wearing parts, and reduces the crushing cost by 35%.

4. At the same time, depending on the variety, the output can reach 50 tons to 300 tons.

Mirant's Hammer Crusher is widely used in mining, smelting, building materials, highways, railways, water conservancy, chemical industry and other industries. They are particularly suitable for crushing limestone and stone with a compressive strength of less than 200 MPa.

Model | YBS-1000 | YBS-1200 | YBS-1600 | Dimension | GZY-2600 | |

CP-0402 | 400×200 | 200 | ≤30 | 8-12 | 800*890*560 | 800 |

CP-0404 | 400×400 | 200 | ≤30 | 16-25 | 980*890*570 | 1050 |

CP-0604 | 600×400 | 200 | ≤30 | 22-33 | 1030*1270*800 | 1430 |

CP-0606 | 600×600 | 200 | ≤30 | 30-60 | 1350*1270*820 | 1770 |

CP-0808 | 800×800 | 200 | ≤30 | 75-105 | 1750*1620*1080 | 3600 |

CP-1010 | 1000×1000 | 300 | ≤30 | 160-200 200-245 | 2100*2000*1340 | 6100 |

CP-1016 | 1000×1600 | 300 | ≤30 | 300-350 400-500 | 2700*2000*1350 | 9200 |

CP-1216 | 1200×1600 | 400 | ≤30 | 500-620 620-800 | 3100*2800*1750 | 15000 |

CP-1221 | 1210×2100 | 400 | ≤30 | 800-1000 | 3620*3350*1950 | 24000 |

1. Advice of model choice.

2. Design and manufacture machines according to customer's special requirements.

3. View our Factory.

To establish long term cooperation, we will regularly call and email our clients, to check the equipment working condition, offer suggestions for maintenance, and if necessary we will pay a visit to clients to solve the problems caused during equipment working.