For lime powder screening, traditional vibrating screens may not be the ideal choice. Circular swing screens have a better screening effect on lime powder. With its unique design structure, the circular swing screen can effectively improve the material screening efficiency, ensure the quality and output of lime powder, and show excellent screening effect in lime powder screening production.

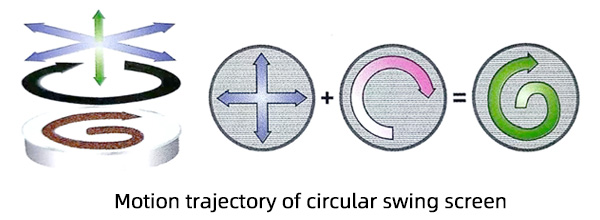

The design and unique structure of the circular swing screen make it the screening equipment closest to manual screening work. It cleverly combines the screen (planar circular motion) and the winnowing (upward parabolic motion). By adjusting the radial angle and tangential angle, the movement route and residence time of the material on the screen surface can be changed to achieve the best screening effect. It is especially suitable for the screening of particulate materials and fine powder materials. Although the price of the lime powder circular swing screen is slightly higher than that of the vibrating screen (linear screen, rotary vibrating screen), it has become a screening equipment favored by manufacturers due to its outstanding performance.

Compared with traditional vibrating screens, the high efficiency of circular swing screens is reflected in:

1. Higher screening efficiency. After comparison, when processing coarse materials below 30 mesh, the output of circular swing screens is equivalent to that of vibrating screens, but the maintenance cost of circular swing screens is lower. When processing materials of 30-500 mesh, the output of circular swing screens is significantly higher than that of vibrating screens, and the service life of the screen is longer;

2. Wider screening area. The screening area of common rotary vibrating screens usually does not exceed 1500mm. If it exceeds this range, it faces a higher maintenance rate. The main reason is that the vibration motor used in large-size rotary vibrating screens has a large power, which will not only affect the screening materials, but also damage the body after long-term operation, especially for large-area frames. The degree of damage is more verified, affecting the effect of multi-layer screening. The circular swing screen uses an ordinary motor. After the speed is changed, the frame performs a low-speed swing motion, and the frame is basically intact. At present, the model range of circular swing screen has expanded to 600mm--2600mm. Not only can the machine models be selected in a variety of ways, but the output range is also wide, which can meet the screening needs of customers with large output and high precision;

3. Maintenance rate and service life. The working principle of the vibrating screen is based on high-speed vibration. This vibration is significantly destructive to the machine itself, and may cause vibration cracking or deformation after long-term use. In many cases, the wear of the screen is not only due to normal use, but also affected by the friction of the machine itself. The vibrating screen generates a lot of noise when working, and its vibration motor has a relatively short service life, which increases the frequency of maintenance. The circular swing screen adopts low-speed swing technology, which not only extends the service life of the equipment, but also reduces maintenance costs and equipment noise, ensuring the maintenance rate and safety of the company's production.

4. Impact on screening materials. Due to its working principle of high-speed vibration, the vibrating screen will have a significant destructive effect on the material, especially the granular crystallized and crispy materials, such as chicken essence, monosodium glutamate, sugar, etc. The shape of these materials is often destroyed during vibration screening. The circular swing screen has less impact on the material through its low-speed elliptical swing motion, and hardly destroys the shape of the material, thereby significantly improving the yield of the material.

However, the current price of vibrating screens and their accessories in the market is relatively low. As a new product with high technical content, the production process of the circular swing screen is more complicated than that of the rotary vibrating screen, so the current price is relatively high. From the perspective of long-term use and comprehensive benefits, the circular swing screen has excellent performance in terms of output, accuracy and service life, and its cost performance far exceeds that of the vibrating screen. As the core equipment product in the field of intelligent screening of Mirant Xinxiang Machinery, the circular swing screen has been recognized by customers for its excellent screening and grading capabilities in the lime powder screening production line. We always take "quality assurance, reputation first, quality-oriented, win-win cooperation" as our purpose, and take customer needs as our guide to ensure the manufacture of high-quality products with stable performance, excellent quality, beautiful appearance and easy operation.